16-axis CNC controller PCAcompactI/O

Add to favorites

Compare this product

Characteristics

- Number of axes

- 16-axis

- Other characteristics

- compact

- Input/output

- I/O

Description

KSE-PCA: a CNC with an attitude.

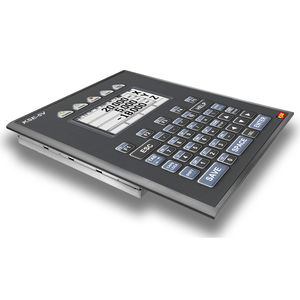

KSE PCA is a flexible and modular control with graphic display and QWERTY keyboard ables to match the most demanding needs of automation up to 16 axes.

Its hw architecture with CPU and boards hosted in a separated cabinet makes it easily adaptable and scalable and suitable for multiple axes systems and machine-centres.

The ISO programming language makes it a perfect solution for complex applications as well as for legacy products.

The KSE-PCA can connect to other controls through Profibus, Ethernet and as master/slave of PLCs. All axes and I/Os are controlled by the integrated PLC.

KSE - PCA

- CNC with operator-panel, modular rack and ISO interpreter

- Dedicated sw versions

- QWERTY keyboard with special keys

- Compact Flash card, USB and Ethernet interfaces

- Ethernet interface for connection to local network and global service

- Soft PLC with AWL programming

- I/O interface based on KSE protocol/CanBus/Profibus for connection of devices and control panels

- Up to 16 axes/spindles

- Window-based GUI and file manager

Solutions:

2AS - application for 2 synced axes/2 closed-loop axes.

3AC1AA - 3 closed-loop axes + 1 open-loop axis application for cutting line with 6-station transfer.

8AA - application for 8 open-loop axes.

A7TF - 2x3 closed-loop axes application for roll-feed + transfer + 1 closed-loop axis for unstacker with electronic cams.

AVRZTF - zigzag press roll-feed with electronic cams with Z-B + C-Q axes.

CFA88 - 8 coilers + 8 rolls application.

FORAC - Boring-machine + manifold driller + puncher application.

FORC_Z - hairpin bender application.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.