- Hydraulics - Pneumatics

- Valve

- Knife gate valve

- Kühme Armaturen GmbH

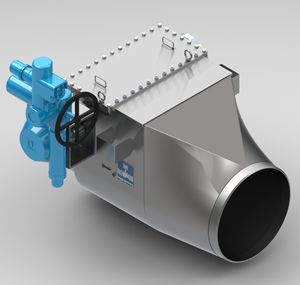

Knife gate valve KSK-HLKwith handwheelshut-offfor gas

Add to favorites

Compare this product

Characteristics

- Type

- knife gate

- Operation

- with handwheel

- Function

- shut-off

- Media

- for gas

- Body

- flange

- Applications

- for solids

- Associated function

- feeding

- Other characteristics

- compact, automatic, thermal

- DN

Max.: 800 mm

(31.496 in)Min.: 150 mm

(5.906 in)- Pressure

0.5 bar

(7.3 psi)- Temperature

300 °C

(572 °F)

Description

COAL DUST DAMPER TYPE KSK-HLK

Coal dust dampers are used in pipings of coal fired power plants between mills and burners. The purpose of these dampers is to shut-off individually the coal feeding line upstream the burner when the corresponding mill is out of service. The coal dust dampers are of heavy duty design with an optimised flow pattern to prevent deposit formation. In opened position the damper flap is positioned completely out of the dust stream which results in full orifice cross section for less pressure drop.

The damper type KSK-HLK comes with an additional hot-air connection. In closed position of the main damper blade hot air injected ensures automatic cooling and cleaning from remaining dust at the burner port. As a result the burner is protected against illegal high temperatures and the boiler is protected against explosion.

Application:

Thermal Power Plants

YOUR BENEFITS

Completely unblocked flow cross section

Reliable shut-off of the medium due to robust seat sealing system

Very short positioning times compared to simple shut-off valves

Compact and cost-efficient solution – only one valve instead of two conventional ones

OPERATION DETAILS

When in its closed position, the flap plate is pressed onto the flap seat by the drive shaft and the internal lever, ensuring a dust-tight shut-off. At the same time, the hot-air connection is opened to cool down the burner gun. When the coal dust flap is opened, the flap plate is moved around 90° and unblocks the entire flow cross section. In this position, the flap plate does not interfere with the flow but seals off the hot air supply completely.

Catalogs

No catalogs are available for this product.

See all of Kühme Armaturen GmbH‘s catalogsRelated Searches

- Valve

- Hand valve

- Control valve

- Pneumatic valve

- Valve with flange

- Regulating valve

- Stop valve

- Lever control valve

- Electric valve

- Biogas valve

- Valve with handwheel

- Pneumatically-operated valve

- Butterfly valve

- Piston actuator valve

- Wedge gate valve

- Valve for the chemical industry

- Valve for industrial applications

- Standard valve

- DIN valve

- ANSI valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.