- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Workpiece loading system MAIROFlex iisywith 6-axis articulated robotautomated

Add to favorites

Compare this product

Characteristics

- Options

- automated, with 6-axis articulated robot, workpiece

Description

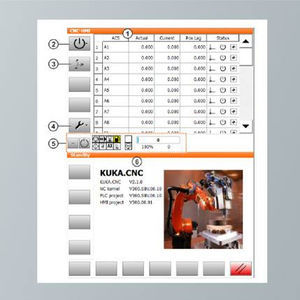

Automated machine loading with a cobot provides unique benefits for companies. That's why KUKA partnered with the technology and automation developer MAIROTEC to create a modular automation cell that loads machines – cost effectively and intuitively.

Based on the KUKA LBR iisy cobot, MAIROTEC developed a machine that can load machines. The objective of the MAIROFlex iisy: Provide a uniquely cost-effective and simple introduction to automation for companies including small and medium-sized enterprises.

In its first real practical application, the cobot automated lathe loading and unloading with small hex steel blocks to be transformed into cylindrical studs. To relieve a metal company's employees, a collaborating robot now carries out this routine task.

When the lightweight robot is used in stud production, a zero point pallet with 96 inserted hex steel blocks is located on the attachment fork. The robot picks it up with the gripper and inserts it precisely into the spindle, where the turning tool begins to machine the stud body after the door has closed. The cobot then removes the finished stud and places it back on the pallet, precise to the millimeter, before it picks up the next part.

Machine loading: manually or with the cobot?

Manual machine feeding is a repetitive, physically stressful and error-prone task. Cobots now frequently tackle machine loading to allow skilled workers to carry out rewarding and complex tasks that match their qualifications.

Catalogs

No catalogs are available for this product.

See all of KUKA AG‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.