- Production Machines

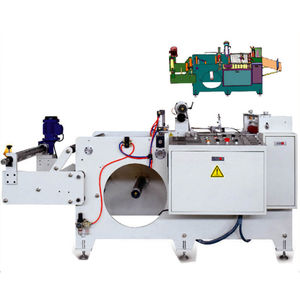

- Cutting Machine

- Ultrasonic cutting machine

- Kunshan Dapeng Precision Machinery Co., Ltd.

Blade cutting machine DP-1400CQultrasonicfor aluminumfor copper

Add to favorites

Compare this product

Characteristics

- Technology

- blade, ultrasonic

- Material

- for aluminum, for copper, for rubber, for vinyl, for leather, for composite materials, for paper, for cardboard

- Product handled

- sheet, roller, belt

- Control type

- PLC-controlled

- Associated function

- unwinding

- Configuration

- compact

- Other characteristics

- automatic, roller

- Laser power

4,500 W

Description

55 inch blade cross cutting machine

has a 55" wide blade, variable speed, adjustable tray and built in automatic unwinder. 220 Volts or 380 Volts , please choose

Able to cut plastic, Lycra, cloth, canvas, denim, rubber, neoprene, graphite, composites, vinyl, paper, cardboard, leather, even metals such as copper and aluminum.

55 inch blade cross cutting machine

packaging paper cutting machine with slitting function

this kind machine employs mircocomputer digital controller to set belt cutting length ,

and its ergonomically designed , easy operation,the depth adjustable knife performs complete cutoff and half cutoff function.

sizing cutting for insulation paper ., plastic sheet and PP film etc

This packaging paper cutting machine with slitting function is suitable for cross cutting the web-form materials. It has features such as computer control, converter speed regulation, constant-length setting, automatic counter, and sound-ray alarm system, etc. Its compact in structure, innovative in design, and high in automation. It is necessary equipment of cross cutting the web-form materials into sheet form materials.

1. Functions :

1, the machine uses microcomputer device, set transverse length, number, volume, etc., with automatic meter.

2, the choice of the central PLC program control and L touch screen operation procedures, Servo motor drives, frequency control.

3, set automatic lifting material platform to reach the sheet after the cut neat, easy to organize.

4, the use of magnetic brakes unwinding tension control, ensuring smooth feeding, consistent tension.

5, the feed mechanism using ultrasonic sensors to control automatic feeding

Catalogs

No catalogs are available for this product.

See all of Kunshan Dapeng Precision Machinery Co., Ltd.‘s catalogsOther Kunshan Dapeng Precision Machinery Co., Ltd. products

Roll To Sheet Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- High-speed cutting system

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Aluminum cutting system

- Sheet cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-efficiency cutting system

- Compact cutting system

- Copper cutting system

- Marking cutting system

- Cutting machine for the electronics industry

- Paper cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.