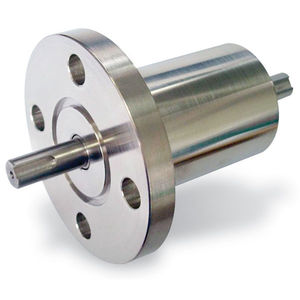

Flow meter feedthrough KLFDBP02510Evacuumrotary

Add to favorites

Compare this product

Characteristics

- Product applications

- for flow meters, vacuum

- Other characteristics

- rotary

Description

These Ferro-Magnetic Fluid sealed rotary feedthroughs are sealed to the baseplate by a fluorocarbon o-ring. The operator mounts these drives to the vacuum chamber by placing them in a suitable smooth-sided port in the chamber wall and using a capture nut. Some models are threaded only part way. They will accommodate various wall thicknesses when used with a sleeve or spacer over the unthreaded portion so that the nut compresses the o-ring.

In vacuum practice, the o-ring is compressed against the vacuum chamber's inner surface to limit virtual leaks. As shown in the dimensional drawings, most of these Ferro-Magnetic Fluid sealed feedthroughs are designed to be installed this way. A few, however, are intended to have the o-ring sealing against the atmosphere side surface. To reduce the virtual leaks associated with the thread, the feedthrough has a flat machined along the length of its threaded portion.

Please refer to the technical notes about loading, temperature, and other relevant information before specifying a feedthrough.

Catalogs

No catalogs are available for this product.

See all of Kurt J Lesker‘s catalogsRelated Searches

- O-ring gasket

- Metal seal

- Rod seal

- Feedthrough

- Shafts seal

- Stainless steel gasket

- Compression gasket

- Wire feedthrough

- Fitting gasket

- Hermetic feedthrough

- Flange feedthrough

- Insulated feedthrough

- Aluminum gasket

- Vacuum feedthrough

- Multiple-element feedthrough

- Single-element feedthrough

- Bronze seal

- Electrical cable feedthrough

- Instrumentation feedthrough

- Rotary feedthrough

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.