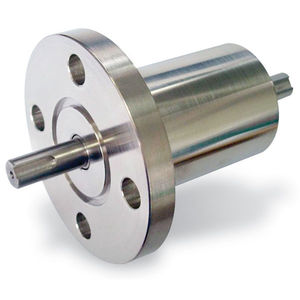

Flow meter feedthrough FE132405vacuumrotary

Add to favorites

Compare this product

Characteristics

- Product applications

- for flow meters, vacuum

- Other characteristics

- rotary

Description

Cartridge mounted ferrofluid rotary feedthroughs can replace existing vacuum shafts or spindles which use dynamic o-ring seals (defined as o-ring seals which press against a moving surface). Dynamic o-ring seals frequently cause leaks in processes using vacuum in a manufacturing environment. To remedy this, replace the shaft having the dynamic seal and select a cartridge feedthrough with an OD that slips inside the seal “well” in the process vacuum wall. The static o-ring seals on the cartridge’s grooved outer surface do not move, making them far less likely to leak than dynamic o-ring seals.

Ferrofluid Feedthrough Features

Use a special magnetic fluid (ferrofluid) in place of an o-ring seal around dynamic parts

Fluid hermetically seals the shaft making a liquid o-ring while a permanent magnet keeps the fluid in place

Ferrofluid magnetically held in stages formed by grooves machined into either the shaft or pole pieces

Unlike regular o-rings, the ferrofluid o-ring remains intact for years of operation despite the shaft’s motion

Catalogs

No catalogs are available for this product.

See all of Kurt J Lesker‘s catalogsRelated Searches

- O-ring gasket

- Metal seal

- Rod seal

- Feedthrough

- Shafts seal

- Stainless steel gasket

- Compression gasket

- Wire feedthrough

- Fitting gasket

- Hermetic feedthrough

- Flange feedthrough

- Insulated feedthrough

- Aluminum gasket

- Vacuum feedthrough

- Multiple-element feedthrough

- Single-element feedthrough

- Bronze seal

- Electrical cable feedthrough

- Instrumentation feedthrough

- Rotary feedthrough

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.