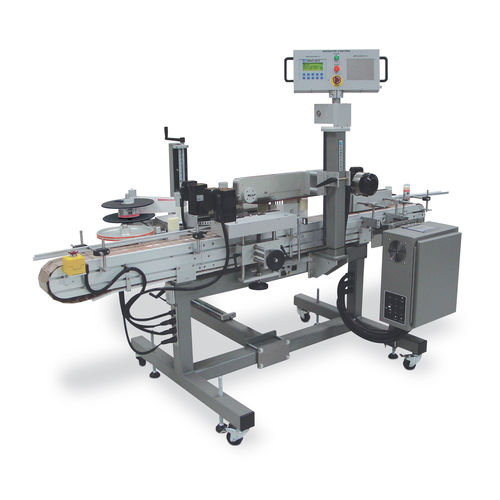

Automatic labeler IL6000Oblongsidein-line

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Label positioning

- side

- Other characteristics

- in-line

Description

The Challenge

A Canadian producer of natural personal care products needed a single labeling system that could wrap apply decorative labels to both their oblong-shaped deodorant stick containers and to their round lotion bottles. Increased throughput, accurate label application, and quick change-overs from one container to another were specific needs that could not be met with their current labeling set up.

The Solution

Label-Aire’s solution was to configure its versatile Inline Series 6000 labeling system with the reliable 3115 Wipe-On applicator and a selection of available options to make the quick change from round to oblong containers (and vice-versa) possible. The result was the Inline 6000 Wrap Labeling System. For round containers, the 6000’s wrap belt spins the moving bottles several times against a padded pressure plate after the point of application, ensuring accurate and wrinkle-free labels every time. After a quick change-over, the oblong-shaped containers must first pass through the 6000’s chain aligner. A top trap holds the product in place while the leading edge of the label is applied to a specific spot on the container. Again, the wrap belt spins the moving containers against a padded pressure plate making several revolutions. By utilizing the Inline 6000’s inherent versatility, Label-Aire was able to provide the customer with a simple and cost-effective solution.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Label Aire‘s catalogsRelated Searches

- Automatic labelling machine

- Bottle labeling machine

- Side labelling machine

- Labeller for the pharmaceutical industry

- Top labelling machine

- Labeller for the beverage industry

- In-line labeler

- High-speed label applicator

- Semi-automatic labelling machine

- Packaging labelling machine

- PLC-controlled labeling machine

- Can labeling machine

- Tube labeling machine

- Bottom labelling machine

- Motorized labeling machine

- Continuous-motion labelling machine

- Wipe-on label applicator

- Extreme condition labeler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.