- Packing - Handling - Logistics

- Packing and Packaging

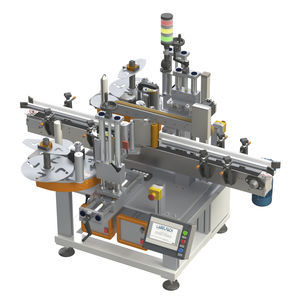

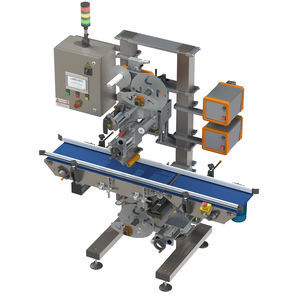

- Automatic labeler

- LABELPACK TRADE SRL

Automatic labeling system MASTER TTfor tubestopfor the cosmetics industry

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product application

- for tubes

- Label positioning

- top

- Applications

- for the cosmetics industry

- Type

- for self-adhesive labels

- Throughput

50 p/min

Description

This innovative solution is designed for labeling empty cosmetic tubes. The tube is fed either manually or automatically and is conveyed to the

main carousel where a series of spindles receive the tube and convey it onto the various stations. Application of labels is controlled by both LABELX 140 ES and a product rotation system with possible

automatic orientation of the label position in respect to the cap opening. The main frame is made in stainless steel with the balcony configuration and the control box position on the back side of the system and safety protection in policarbonate. The labelling system is managed by a PLC with Touch Screen operator panel.

• STANDARD FEATURES

Labelling unit LABEX 140 ES

Horizontal and vertical micro regulation unit with numeric indicators

Semi-automatic product feeding device

Conveying module with 6 position mechanical wheel

Product rotating device

Automatic speed synchronization

MASTER main frame

Total protections in transparent polycarbonate

Centralized electronic control with Touch screen operator panel

PLC unit with memory of setting parameters

• OPTIONAL ACCESSORIES

LABELX 250 ES

Pre-end of roll alarm

Ultrasonic sensor for transparent labels

label orientation sensor

VIDEO

Catalogs

MASTER TT

1 Pages

Related Searches

- Automatic labelling machine

- Bottle labeling machine

- Side labelling machine

- Labeling machine for the food industry

- Labeller for the pharmaceutical industry

- Labeler for the cosmetics industry

- Top labelling machine

- Labeller for the beverage industry

- Wrap-around labelling machine

- Compact labelling machine

- In-line labeler

- Roll tag

- High-speed label applicator

- Semi-automatic labelling machine

- White tag

- Packaging labelling machine

- Industrial tag

- Printable tag

- Labeler for the chemical industry

- Rectangular tag

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.