- Packing - Handling - Logistics

- Packing and Packaging

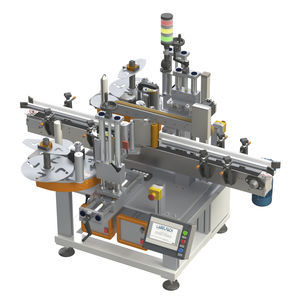

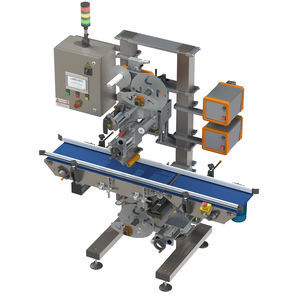

- PLC-controlled labeler

- LABELPACK TRADE SRL

PLC-controlled labeling system MASTER BS-DS-WAfor bottlessidefor the cosmetics industry

Add to favorites

Compare this product

Characteristics

- Operational mode

- PLC-controlled

- Product application

- for bottles

- Label positioning

- side

- Applications

- for the cosmetics industry, for the pharmaceutical industry

- Type

- for self-adhesive labels

- Other characteristics

- wrap-around

Description

The system is equipped with a first station for applying a label on the bottom of jars for creams with thermal transfer printing of the production lot number and other variable data. Subsequently, an orbital aligner device guarantees correct alignment of bottles with an elliptical base. Two LABELX labeling units provide for the application of front and back labels on bottles with a quadrangular or elliptical base. One of these units is fixed on a mechanical slide which allows it to be moved towards the dynamic rotation device which allows the application of a wrap-around label on cylindrical-shaped jars. This labeling unit is also equipped with a thermal transfer encoder for variable data printing. The system is equipped with controls for the successful application of labels and an automatic ejector. System control is entrusted to a PLC with touch screen operator panel equipped with access for remote assistance management. Ind. 4.0 Ready

• STANDARD FEATURES

LABELX 140 ES labellers - n. 3

TTO thermal transfer printers - n. 2

Transport system with two parallel belts

Main transport system with flat belt

Product stabilizer device

Orbital aligner device

Dynamic product rotation device

Check that the application has been made with an ejector

Management PLC with storage of operating parameters

VIDEO

Catalogs

No catalogs are available for this product.

See all of LABELPACK TRADE SRL‘s catalogsRelated Searches

- Automatic labelling machine

- Bottle labeling machine

- Side labelling machine

- Labeling machine for the food industry

- Labeller for the pharmaceutical industry

- Labeler for the cosmetics industry

- Top labelling machine

- Labeller for the beverage industry

- Wrap-around labelling machine

- Compact labelling machine

- In-line labeler

- Roll tag

- High-speed label applicator

- Semi-automatic labelling machine

- White tag

- Packaging labelling machine

- Industrial tag

- Printable tag

- Labeler for the chemical industry

- Rectangular tag

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.