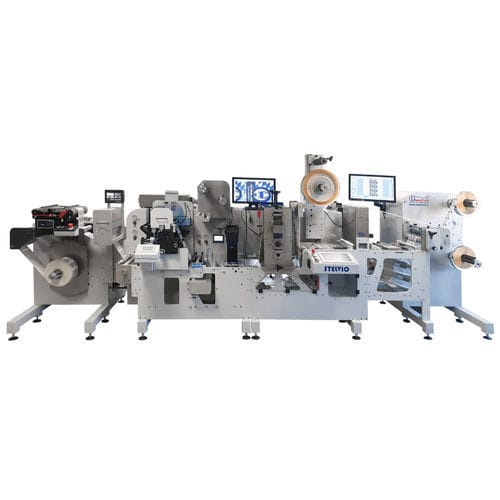

Modular converting machine higly configurable, from blank die cut production to high quality label embellishment

Main features

•BOSCH REXROTH electronics, servo drive motors on nip roll and rewinders

•Servo driven 800mm unwinder with Energy recovery, for a significative cost saving

•Webguide with ultrasonic sensor and movable splicing table with pneumatic clamps

•Full rotary die cut to register with +/- 15mm lateral adjust

•servo driven matrix rewinder with diameter sensor and matrix rupture sensor

•Mechanical speed up to 150m/min

•Display 12” color touch screen with step by step instructions

•Storable job recipes with quick recall by name, customer and favourites

•Remote service and production data export

•Stop production with label counter, length and final diameter

•Automatic stop at unwinder end of roll

•Ultrasonic label counter

•2 in 1 slitting system, to pass from rotary to razor in few minutes with no additional devices

•Rewinder with servo drive motorization

•Available size 330mm, 430mm

Available optionals

•Semi rotary die cut module

•Third part magnetic cylinder compatibilità

•Anvil fine adjust with pressure gauge indicators

•Flexo station for varnish and print to register

•Cold foil unit

•PRINT BAR for digital screen printing

•Quality control camera

•Inkjet marker for variable data, datamatrix etc

•LAVAREDO automatic slitter positioning system for both rotary and razor

•Second rewinder with independent servo drive motorization

•Semi automatic turret rewinder VAJOLET

•Corona threatment