- Electricity - Electronics

- Electronic Component

- Voltage coil

- Laboratorio Elettrofisico

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Magnetizing coil Bitter 2-Pole Axial Magnetizationhigh-voltageaxial2-pole

Add to favorites

Compare this product

Characteristics

- Technology

- magnetizing

- Electrical characteristics

- high-voltage

- Configuration

- axial, 2-pole

- Applications

- for solenoid valves, for industrial applications, for automotive applications, for electric micro motors, for rotors, for stepper motors

- Other characteristics

- high-performance

Description

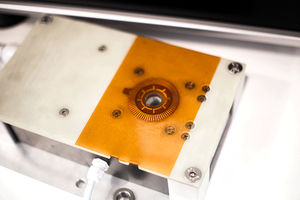

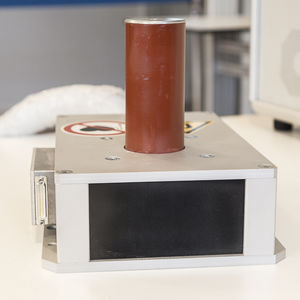

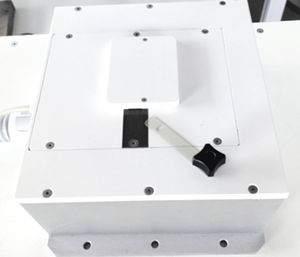

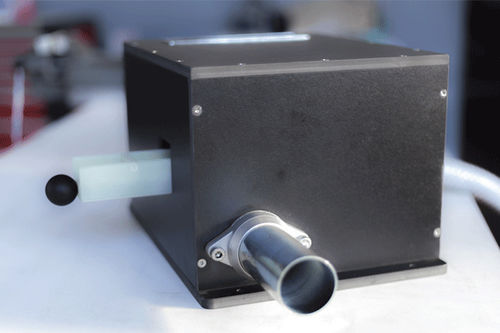

Bitter axial coil is composed of copper sheets. These sheets are cut with a pattern that forces the electric current to run along the inner edge, and run around the hole, within which is the magnetizing volume. The coil sheets are then connected to each other in stacks. The remaining sheet metal around each conductive path acts as a thermally conductive fin — with a surface area much larger than a wire of comparable size would have. This fixture is encased in an IP30 box.

Key benefits

Excellent heat dissipation

Better strength resistance

Constructed without epoxy for a longer life span

LE EQUIPMENT FOR ALL MAGNETIZATION SHAPES

Most of the time a magnetization area is circular or rectangular; but magnetization is quite often axial. Radial magnetization is also possible with two opposing solenoids with our split solution

Catalogs

No catalogs are available for this product.

See all of Laboratorio Elettrofisico‘s catalogsOther Laboratorio Elettrofisico products

magnetizing fixtures

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.