- Metrology - Laboratory

- Metrology and Test Equipment

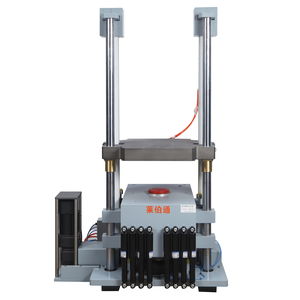

- Shock testing machine

- Labtone Test Equipment Co., Ltd.

Impact testing machine SKM800shockcomputer-controlledfor electronic components

Add to favorites

Compare this product

Characteristics

- Test type

- impact, shock

- Operating mode

- computer-controlled

- Test material

- for electronic components, for weapon sight

Description

200KG bump shock test machine for weapon sight shock testing

Product Introduction

Components and other electronic and electrical products may experience repeating impact during transportation or use. Bump test can be used as a method to ensure the design structure is satisfying or as a quality assurance method. Specimen will experience regular peak acceleration and continuous impact with standard pulse during the bump test.

Packaging & Shipping

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case,which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless,moisture corrosion, good transparency etc

Services

Pre-sales:

Technical consultation: test method, laboratory planning and suggestion.

Equipment selection: selection scheme, FAQ.

Product testing scheme.

In-Sales:

Customer communication and progress report.

Guidance for pre-installation preparation, equipment commissioning and test run.

Calibration (when Third Party’s verification is required).

After-Sales:

Technical training: operation of equipment, daily maintenance, common fault diagnosis and troubleshooting.

Scheduled on-site service: Detection of problem as soon as possible in order to eliminate equipment and anthropogenic hazards. This is to ensure long term and stable equipment operation as well as delivery of latest technical information.

Technical support: special paid services are provided according to customer’s needs.

Catalogs

No catalogs are available for this product.

See all of Labtone Test Equipment Co., Ltd.‘s catalogsOther Labtone Test Equipment Co., Ltd. products

Bump Test Machine

Related Searches

- Test machine

- Test cabinet

- Test stand

- Material testing machine

- PC-controllable testing machine

- Automatic test machine

- Temperature test cabinet

- Climatic test chamber

- Vertical test machine

- Humidity test cabinet

- Industrial test machine

- Industrial testing system

- Laboratory test machine

- Precision test machine

- Electromechanical test machine

- Research and development test machine

- Hydraulic test machine

- Environmental test cabinet

- Manual test kit

- Automobile test cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.