- Metrology - Laboratory

- Metrology and Test Equipment

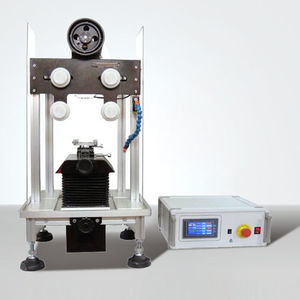

- Micro Vickers hardness tester

- Laizhou Weiyi Experiment Machine Manufacturing Co., Ltd.

Micro Vickers hardness tester HV-1000TPTA benchtopfor non-ferrous metalsfor steel

Add to favorites

Compare this product

Characteristics

- Type

- micro Vickers

- Mounting

- benchtop

- Product applications

- for non-ferrous metals, for steel, for ceramics, device, shaft

- Other characteristics

- LCD digital display, with control panel, automatic, micro

- Norms

- ISO 6507, ASTM E384

- Load

Max.: 1 kgf

Min.: 0 kgf

- Useful height

90 mm

(3.5 in)- Weight

36 kg

(79.4 lb)

Description

● Automatic turret, high-precision optical measuring systems, precision coordinate test sets.

● Experimental process automation, simple operation, no thought operator error.

● Frictionless loading shaft, high precision testing force, optional CCD imaging device and image processing system.

● Optional Knoop indenter Knoop hardness test performed.

● Automatic data input, LCD automatically displays hardness values, the random printer hardness test results

● Hardness conversion between different hardness scales

● Precision conforms to GB/T 4340.2, ISO 6507-2 and ASTM E384

Application

It can be used to determine the Vickers hardness of steel, non-ferrous metals, ceramics, treated layers of metal surface, and the hardness grads of carburized, nitrided and hardened layers of metals. It is also suitable to determine the Vickers hardness of micro and super thin parts.

Specification

Measuring range:5-3000HV

Power supply: 220V, 50/60Hz

Weight: 36kg

Test force: 0.09807, 0.2452, 0.4904, 0.9807, 1.961, 2.942, 4.904, 9.807N (10, 25, 50, 100, 200, 300, 500, 1000gf)

Max. height of test piece: 90mm

Depth of Throat:110mm

Magnifications of the measuring system: 400X,100X

Dimensions: 500 x 240 x 530mm

VIDEO

Catalogs

No catalogs are available for this product.

See all of Laizhou Weiyi Experiment Machine Manufacturing Co., Ltd.‘s catalogsOther Laizhou Weiyi Experiment Machine Manufacturing Co., Ltd. products

Hardness Test

Related Searches

- Indentation hardness tester

- Benchtop indentation hardness tester

- Digital hardness tester

- Rockwell indentation hardness tester

- Brinell indentation hardness tester

- Vickers indentation hardness tester

- Automatic indentation hardness tester

- Portable indentation hardness tester

- Metal indentation hardness tester

- Steel indentation hardness tester

- Superficial indentation hardness tester

- Analog hardness tester

- Shore hardness tester

- Plastic hardness tester

- Micro Vickers hardness tester

- Micro indentation hardness tester

- Hardness tester with control panel

- Leeb hardness tester

- Ceramic hardness tester

- Ferrous metal hardness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.