- Products

- Catalogs

- News & Trends

- Exhibitions

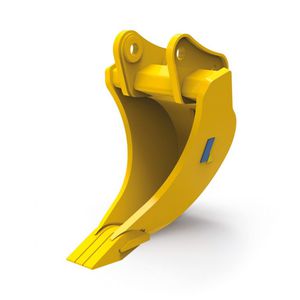

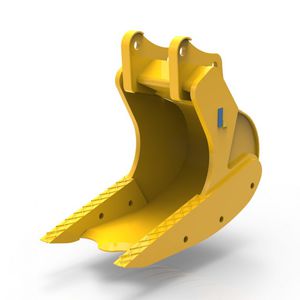

Standard tooth bucket for excavatorsfor mining

Add to favorites

Compare this product

Characteristics

- Type

- standard tooth

- Load-bearing

- for excavators

- Other characteristics

- for mining

- Carrier weight

Min.: 120 t

(132 us ton)Max.: 400 t

(441 us ton)

Description

The backhoe bucket is LAMETER’s best-selling product for mines and quarries.

Our backhoe buckets have been working for over 20 years to extract minerals and rocks from mines around the world, in heavy duty and extra heavy duty applications.

Each individual bucket can be adapted to different applications and customer needs.

Custom fit

Thanks to the use of the most up-to-date technologies and the use of 3D scanners, we are able to acquire the dimensions of machines and equipment in mines around the world, to design tailor-made and ensure the maximum precision of our equipment.

Configuration

We customize the buckets using spare parts and coatings of all brands and models, according to the customer's request. We use original or interchangeable cylinders, lubrication kits, bushings, dust guards, covers and castings.

For all machines

We produce front buckets in mine application starting from the 120 Tons class up to 400 Tons of operating weight of the machine.

Special steels

We use special anti-wear and high-strength steels up to 160 mm thick, compliant with current regulations and equipped with a valid production certificate.

VIDEO

Related Searches

- Bucket

- Excavator bucket

- Earthmoving bucket

- Loader bucket

- Quick coupler

- Log grapple

- Screening bucket

- Excavator quick coupler

- Standard tooth bucket

- Hydraulic quick coupler

- Light material bucket

- 5 teeth bucket

- Mining bucket

- Dozer blade

- Skeleton bucket

- Ripper tooth

- Loader quick coupler

- Face shovel bucket

- Skid steer loader dozer blade

- Excavator ripper tooth

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.