- Products

- Catalogs

- News & Trends

- Exhibitions

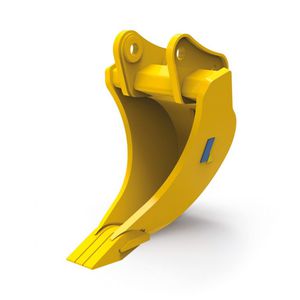

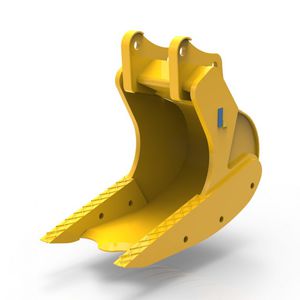

Excavator ripper tooth

Add to favorites

Compare this product

Characteristics

- Type

- for excavators

Description

The Ripper Tooth is designed for the detachment of blocks but is also used for demolition of very hard soil. The effort focused on a small area, the shape and structure of the ripper tooth ensure the best performance of the excavator.

The Ripper Teeth can be designed with either direct fit or quick coupling with any brand of customer’s choice available on the market.

CONFIGURATOR

Tailor Made

Using the most advanced technologies and 3D scanners, we can detect machine and attachment dimensions in mines all over the world, to tailor-made designs and guarantee the utmost precision of our equipment.

High Steel Quality

Rippers are manufactured using wear resistant and high strength steels up to 160mm thickness. All materials used are compliant with the current regulations and have a valid production certificate.

Configuration

The Ripper Teeth are arranged with one thick tip made of wear-resistant steel, or equipped with a weld-on nose and interchangeable tip in various models and brands, depending on the customer’s preferences. It’s also possible to fit “wear parts” such as chocky bars or bolt-on protectors to extend rippers’ life.

Machines Sizes

Lameter produces Ripper Teeth for Quarry application starting from 30 Tons up to 260 Tons of excavator operating weight.

Related Searches

- Bucket

- Excavator bucket

- Earthmoving bucket

- Loader bucket

- Quick coupler

- Log grapple

- Screening bucket

- Excavator quick coupler

- Standard tooth bucket

- Hydraulic quick coupler

- Light material bucket

- 5 teeth bucket

- Mining bucket

- Dozer blade

- Skeleton bucket

- Ripper tooth

- Loader quick coupler

- Face shovel bucket

- Skid steer loader dozer blade

- Excavator ripper tooth

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.