- Products

- Catalogs

- News & Trends

- Exhibitions

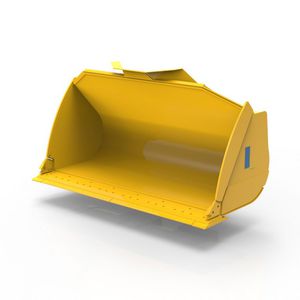

Leveling pallet fork for wheel loader

Add to favorites

Compare this product

Characteristics

- Type

- leveling

- Product applications

- for wheel loader

- Carrying capacity

30 t

(33.1 us ton)

Description

LAMETER manufactures fork kits that are used for handling blocks in the quarry, designed and produced for over 30 years and are the result of experience in the quarries of Carrara and around the world.

More than 500 seal kits are currently working successfully in block quarries on all continents.

Lameter produces fork kits for wheel loaders starting from the 23 Tons operating weight class, designed with a total capacity from 26 Tons to 200 Tons both with direct coupling and with quick coupling of any brand.

Each single fork kit is built with special high-strength wear-resistant steels and can be customized according to customer needs.

At the customer’s request, to avoid damaging the transported blocks or the machine itself, we also install additional protections.

All our forks are covered by a 2 year guarantee against breakage.

We also always have various spare forks and ready-to-use kits available, to limit downtime during repairs.

The forged forks, made with the best high-strength steels, make it possible to reduce their thickness, maintaining capacity and optimizing work in the quarry.

the forks are forged in a single piece of special steel to our specifications, and equipped with a capacity certificate in accordance with UNI ISO 2330: 2006.

These forks guarantee resistance to wear and elasticity

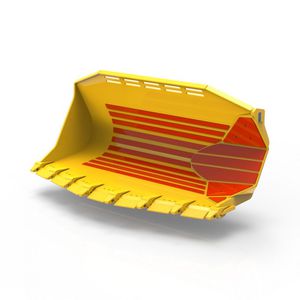

Lamellar forks

The lamellar forks were created to anticipate the new needs of the market.

Lameter has studied and developed lamellar forks by welding shaped steel with a high yield point, combining excellent wear resistance. The improved weldability of these forks promotes quick repair in case of breakage.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.