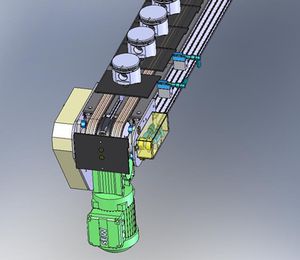

Electric press P seriesbendingstraighteningpunching

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Function

- bending, straightening, punching, assembly, test

- Other characteristics

- servo-driven

- Force

Min.: 30 kN

Max.: 150 kN

- Stroke

Min.: 150 mm

(5.906 in)Max.: 400 mm

(15.748 in)- Working speed

200 mm/s

Description

Lammas is the official distributor for the Italian market of Transligne/Lammas servopress systems.

Servo press is an actuator that converts the rotary motion of the brushless motor into a linear motion of the pressing stem through a recirculating ball or a planetary roller screw. The control of the pressing stem takes place in open ring through the encoder installed on the brushless motor. In addition to the encoder one force sensor (load cell) is installed that measures the force transmitted by the pressing stem during work.

An appropriately programmed logic control unit manages the press working cycle, modulating the descending speed of the pressing stem and analyzing the measured values by these two transducers (encoder and force sensor) during the working phases. The values of displacement and force are used by the software installed in the logic control to generate a mathematical model (force VS position) that is generated in each work cycle. Each mathematical model generated by the system is compared to a sample model stored in the software. The sample mathematical model corresponds to values assumed in a qualitatively perfect process. If the values of the memorized mathematical model correspond with those recorded each cycle means that the processed product has been executed with the same qualitative parameters.

A list of the applications where the servo presses are used is as follows:

Component driving

joints

Riveting

crimping

Pressing

clinching

coining

Pressing

Catalogs

No catalogs are available for this product.

See all of LAMMAS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.