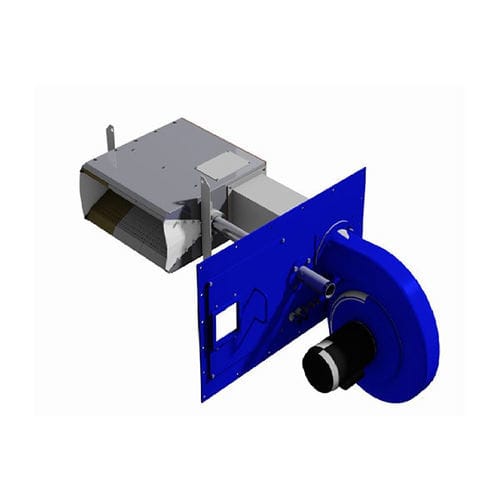

For high output applications, the FDB burner – which incorporates a combustion air fan – creates a genuine packaged option.

FDB burners are able to provide up to twice the heat output when compared with the DB alternative and they can also be operated within a wider range of variable process air flow conditions.

- APL technology – gas and combustion air modulating control

- Heat input range – 175 kW to 1,400 kW

- Ideal for variable plant operating conditions

- Choice of operating fuels

FDB burners offer an alternative short rectangular flame profile compared to the circular combustion output provided by the alternative FDGA range.

Like the FDGA burner range, FDB burners can incorporate Lanemark’s ‘Air Pressure Lead’ (APL) technology, so that all FDB series burners offer an excellent combination of combustion efficiency and emissions control and are especially suited to systems utilizing variable process airflows.

Variable combustion air fan speed control combined with modulating mono-block gas valve technology ensures that safe and efficient gas/air ratios are maintained even under changeable plant operating conditions. Units offer a choice of operation on either natural gas or propane and are particularly suitable for direct fired operations where short flame lengths are a priority.