- Materials - Tools - Components

- Semi-finished products

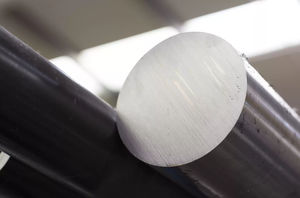

- Rod alloy steel

- Langley Alloys Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Rod alloy steel 32760 for the plastics industrycorrosion resistanthigh-strength

Add to favorites

Compare this product

Characteristics

- Shape

- rod

- Applications

- for the plastics industry

- Other characteristics

- corrosion resistant, high-strength, annealed, stainless steel

Description

Alloy 32760 is a super duplex stainless steel supplied in the hot worked and solution annealed condition. As a super duplex stainless steel, it combines the desirable aspects of both austenitic and ferritic grades. The higher chromium, molybdenum and nitrogen contents result in a Pitting Resistance Equivalent number (PREN) of >40, providing pitting and crevice corrosion resistance superior to austenitic and duplex stainless steels in almost all corrosive media, and a Critical Pitting Temperature exceeding 50°C nb. versions of the PREN formula also include W as a positive influence on overall pitting resistance.

It provides higher strength than both austenitic and 22% Cr duplex stainless steels, and is listed in NACE MR 0175 for sour service and ASME for pressure vessel applications.

Key Features:

Pitting Resistance Equivalent number (PREN) of >40

Critical Pitting Temperature exceeding 50°C

High resistance to abrasion, erosion and cavitation erosion

Listed in NACE MR 0175 for sour service

ASME Approval for Pressure Vessel application

Applications:

Equipment handling organic & fatty acids

Marine industry and shipbuilding propellers, shafts, rudders, shaft seals, pumps, bolts, fasteners, valves, instrumentation

Oil and chemical tankers

Oil & Gas industry pumps, valves, pipe, vessels, wellhead equipment, subsea equipment

Pollution control systems, fans and pumps, wet scrubbers, incinerators, flue gas desulphurisation (FGD)

Pulp & paper industry components such as black liquor heater tubes, digester blow valves, rotary feed valves, I.D.fans, brownstock washers, precipitators, bleaching components

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.