- Materials - Tools - Components

- Semi-finished products

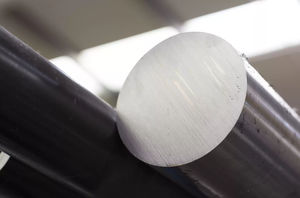

- Rod alloy steel

- Langley Alloys Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Rod alloy steel 32750 for the plastics industrycorrosion resistanthigh-strength

Add to favorites

Compare this product

Characteristics

- Shape

- rod

- Applications

- for the plastics industry

- Other characteristics

- corrosion resistant, high-strength, annealed, stainless steel

Description

Alloy 32750 is a super duplex stainless steel supplied in the solution annealed condition. As a super duplex stainless steel, it combines the desirable aspects of both austenitic and ferritic grades. The higher chromium, molybdenum and nitrogen contents result in a Pitting Resistance Equivalent number (PREN) of >41, providing pitting and crevice corrosion resistance superior to austenitic and duplex stainless steels in almost all corrosive media, and a Critical Pitting Temperature exceeding 50°C.

Supplied in the annealed condition, it achieves yield strengths of 80ksi (550Mpa), greater than most austenitic and duplex stainless steel grades. It cannot be hardened by heat treatment but can be strengthened by cold working. It also exhibits a low coefficient of thermal expansion and higher heat conductivity than austenitic steels and is suitable for working temperatures up to 300°C. Alloy 32750 is listed in NACE MR 0175 for sour service and having gained ASME Approval for Pressure Vessel applications it can be used in a wide variety of applications.

Key Features:

Pitting Resistance Equivalent number (PREN) of >41

Critical Pitting Temperature exceeding 50°C

High resistance to abrasion, erosion and cavitation erosion

Listed in NACE MR 0175 for sour service

ASME Approval for Pressure Vessel application

Applications:

Process industry components in nitric acid, dioxide, polypropylene & PVC production, caustic evaporators

Equipment handling organic & fatty acids

Marine industry and shipbuilding propellers, shafts, rudders, shaft seals, pumps, bolts, fasteners, valves, instrumentation

Oil and chemical tankers

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.