- Materials - Tools - Components

- Semi-finished products

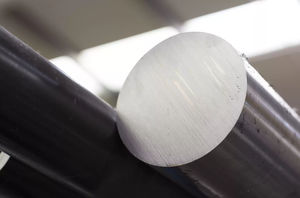

- Rod alloy steel

- Langley Alloys Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Rod alloy steel Ferralium 255 – 3AFfor the plastics industrycorrosion resistantannealed

Add to favorites

Compare this product

Characteristics

- Shape

- rod

- Applications

- for the plastics industry

- Other characteristics

- corrosion resistant, annealed, stainless steel

Description

Ferralium® 255 – 3AF is a super duplex stainless steel which is supplied in either a hot worked condition, annealed or aged condition.

By subjecting the product to an additional ageing process, it is possible to further increase the tensile strength of the product whilst retaining the products high levels of ductility.

As a variant of our unique Ferralium® 255 – SD50 product, it is a 25% Cr alloy with significant additions of Cu, offering excellent corrosion resistance in a wide variety of corrosive chemicals including sulphuric, nitric and phosphoric acid. When exposed to seawater and other chloride containing environments, it also provides outstanding resistance to pitting and crevice corrosion, with a critical pitting temperature exceeding 50°C.

Excellent ductility and impact strength are retained at both ambient and sub-zero temperatures, despite the elevated strength levels. These are also combined with a high resistance to abrasion, erosion and cavitation erosion. Listed in NACE MR 01 75 for sour service and having gained ASME Approval for Pressure Vessel applications, Ferralium® 255-3AF is tested to the highest degree using tests designed to guarantee that the trade-marked product possesses high integrity, a correct phase balance and the absence of sigma and other deleterious phases.

Key Features:

Ferralium® was developed in the 1960’s, pioneering the addition of nitrogen, to create the first super duplex stainless steel

The product was then further developed throughout the 1990’s to extend PREN > 40, and more recently to increase its mechanical properties

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.