- Materials - Tools - Components

- Semi-finished products

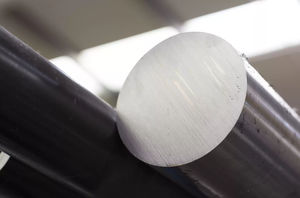

- Rod alloy steel

- Langley Alloys Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Rod alloy steel Ferralium® 255 – 3SFfor the plastics industrycorrosion resistanthigh-strength

Add to favorites

Compare this product

Characteristics

- Shape

- rod

- Applications

- for the plastics industry

- Other characteristics

- corrosion resistant, high-strength, stainless steel

Description

Ferralium® 255 – 3SF is a super duplex stainless steel supplied as forgings. As a 25% Cr alloy, with significant additions of Cu, it offers excellent corrosion resistance in a variety of corrosive chemicals including, but not limited to, sulphuric, nitric and phosphoric acid.

In seawater and other chloride contaminated environments it also provides outstanding resistance to pitting and crevice corrosion, with a critical pitting temperature exceeding 50°C.

Key Features:

Particularly suitable for larger components as the formation of sigma phase is much less likely than it is for other Super Duplexes

Ferralium® was originally developed in 1960’s, pioneering the addition of nitrogen, to create the first super duplex stainless steel

Continuously developed through 1990’s to extend PREN > 40, and more recently to increase mechanical properties

Pitting Resistance Equivalent (PREN) >40, indicating outstanding resistance to pitting and crevice corrosion

Higher copper content provides self-healing effect at sites of pitting to inhibit further growth

Available as bars, plate, pipe and fittings with complementary weld wire

Listed in NACE MR 0175 for sour service

Applications:

Oil & Gas industry pumps, valves, wellhead and subsea equipment

Pollution control scrubbers, precipitators, fans and pumps

Marine propellers, shafts, rudders, seals, pumps, valves

Bolts and fasteners

Grain and vegetable processing plant, sugar cane centrifuges

Pulp and paper digester blow vales, feed valves, washers, black liquor heater tubes, bleaching components

Copper smelting fans, tuyere bars, wet scrubbers, leaching area precipitators

Water and sewage treatment, desalination, swimming pools

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.