- Products

- Catalogs

- News & Trends

- Exhibitions

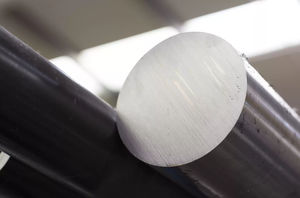

Tubular alloy steel Ferralium® 255 for the plastics industrycorrosion resistanthigh-strength

Add to favorites

Compare this product

Characteristics

- Shape

- tubular

- Applications

- for the plastics industry

- Other characteristics

- corrosion resistant, high-strength, stainless steel

Description

Ferralium® 255 is a super duplex stainless steel supplied in the cold finished and annealed condition. As a 25% Chromium alloy, with significant additions of Copper, it offers excellent corrosion resistance in a wide variety of corrosive chemicals including sulphuric, nitric and phosphoric acid. In seawater and other chloride containing environments it also provides outstanding resistance to pitting and crevice corrosion, with Critical Pitting Temperature exceeding 50°C. Excellent ductility and impact strength at both ambient and sub-zero temperatures combine with a high resistance to abrasion, erosion and cavitation erosion.

In its various product forms, Ferralium® 255 is listed in NACE MR 0175 for sour service and gained ASME Approval for Pressure Vessel applications. It has been tested to the highest degree using tests designed to guarantee that the trade-marked product possesses high integrity, a correct phase balance and the absence of sigma and other deleterious phases.

Specifications

Alloy 255 (Super Duplex 255)

1.4507

X2CrNiMoCuN 25-6-3

Z3 CNDU 25-07 Az

Norsok MDS D51

ASTM A790

ASTM A815

Key Features:

Originally developed in 1960’s, pioneering the addition of nitrogen, to create the first super duplex stainless steel

Continuously developed through 1990’s to extend PREN > 40

Higher copper content provides self-healing effect at sites of pitting to inhibit further growth

Available as bars, plate, pipe and fittings with complementary weld wire

Applications:

Oil & Gas industry equipment

Pulp and paper applications such as black liquor heater tubes

Water and sewage treatment, desalination, swimming pools

Grain and vegetable processing plant

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.