- Materials - Tools - Components

- Semi-finished products

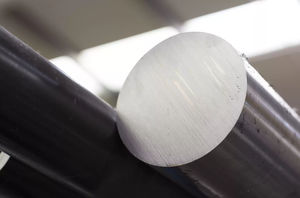

- Rod alloy steel

- Langley Alloys Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Rod alloy steel corrosion resistanthigh-strengthlow carbon

Add to favorites

Compare this product

Characteristics

- Shape

- rod

- Other characteristics

- corrosion resistant, high-strength, low carbon, annealed, stainless steel

Description

Alloy 316L is an austenitic stainless steel supplied in the hot worked and annealed condition. The addition of Mo provides the product with much improved corrosion resistance compared with Alloy 304, particularly with respect to pitting and crevice corrosion in chloride environments. Alloy 316L resists atmospheric corrosion, as well as, moderately oxidising and reducing environments. It also resists corrosion in polluted marine atmospheres. The alloy has excellent resistance to intergranular corrosion in the as-welded condition.

It also provides higher creep, stress-to-rupture and tensile strength at elevated temperatures than a basic Alloy 304. As a fully austenitic grade it possesses excellent toughness, even down to cryogenic temperatures. This low carbon version of Alloy 316 is immune from the sensitisation caused by the precipitation of carbides at grain boundaries when heated, resulting in its widespread use in larger section welded components. It is readily formed and machined, although its relative toughness means that better machining is generally achieved at lower speeds with heavier feeds.

Specifications

1.4404

ASTM A479/A276

S31603

Key Features:

Pitting Resistance Equivalent number (PREN) of 25 compared with 19 for Alloy 304

Excellent ductility and impact strength at both ambient and sub-zero temperatures

Low carbon version of Alloy 316 thereby immune from grain boundary sensitisation

Excellent forming and welding characteristics

Non-magnetic except after significant welding or cold working

Applications:

Process industry equipment in chemical containers, transport units, heat exchangers and organic & fatty acid production

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.