- Materials - Tools - Components

- Semi-finished products

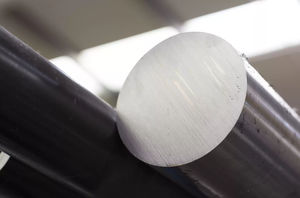

- Rod alloy steel

- Langley Alloys Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Rod alloy steel Fermonic® 60corrosion resistanthigh-strengthannealed

Add to favorites

Compare this product

Characteristics

- Shape

- rod

- Other characteristics

- corrosion resistant, high-strength, annealed, stainless steel

Description

Fermonic® 60 is a fully austenitic alloy supplied in the hot worked and annealed condition (it is also known as Nitronic® 60 – a trademark owned by AK Steel Corporation). The general corrosion resistance is between that of Alloy 304 and Alloy 316 stainless steel, whereby is it generally better than Alloy 304 in most environments but superior to Alloy 316 with respect to chloride pitting resistance. More significantly, additions of Silicon and Manganese provide superior wear, galling and fretting resistance than many other corrosion resistant alloys making it preferable for applications where there is repeated movement/sliding or frequent assembly/disassembly.

These compositional additions also provide almost double the yield strength of Alloys 304/316, and higher strength can be achieved through cold working. Importantly, it remains fully austenitic – and therefore, fully non-magnetic – even after severe cold-working, although there is no improvement in galling performance from this operation.

Specifications

ASTM A479/A276

UNS S21800

Nit60

Notes:

Tensile testing shall be carried out in accordance with ASTM A370 or EN10002-1

Key Features:

Superior resistance to galling and associated wear mechanisms

Retention of mechanical properties up to 1200°C combined with good oxidation resistance

Cost effective alternative to Cobalt- and Nickel-based alloys in wear/galling critical applications

Readily strengthened by cold-working

Non-magnetic

Readily fabricated and welded in the same way as Alloy 304/316

Applications:

Fasteners

Pins and bushings

Wear rails and guides

Roller bearings

Marine shafts

Pump components such as seals and wear rings

Valve stems, seats and trim

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.