- Materials - Tools - Components

- Semi-finished products

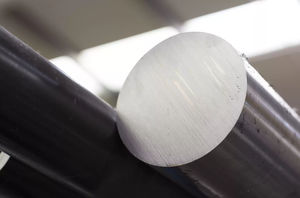

- Nickel alloy rod

- Langley Alloys Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Nickel alloy rod 718 corrosion-resistanthigh-temperatureannealed

Add to favorites

Compare this product

Characteristics

- Shape

- rod

- Other characteristics

- corrosion-resistant, high-temperature, annealed

- Diameter

15.88 mm, 254 mm

(0.63 in, 10 in)

Description

Alloy 718, often referred to as Inconel 718 (where Inconel is a trademark of Special Metals Corp), is a high-strength, corrosion-resistant nickel chromium alloy supplied in the hot worked, solution annealed and age hardened condition.

The addition of Nb, Ti, Al and Ni form a series of precipitates during the controlled solution annealing and ageing process steps, resulting in a significant increase in strength and hardness compared with alternative nickel alloys. These tensile and creep rupture properties are maintained from cryogenic to elevated temperatures, making it suitable for applications between -250oC – 650oC.

As a nickel chromium alloy it possesses acceptable corrosion resistance in a range of environments including sea water, hydrogen sulphide, CO2, elemental sulphur and chloride ions over various temperatures. It is resistant to sulphide stress cracking and is capable of passing the sulphide stress corrosion test in accordance with NACE TM 0177 Method C solution A.

Inconel 718 is perhaps the most widely known and specified grade within this family of alloys. It was introduced in the 1960’s and initially used in the aerospace industry, but due to its ready availability in the market it was taken-up by the oil and gas industry. This was associated with wells moving offshore, drilling deeper with higher temperatures, pressures and corrosive contaminants.

Other nickel-based alloys such as Hastelloy C276 and Inconel 625 provided sufficient corrosion resistance, but insufficient strength without extensive cold working.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.