- Products

- Catalogs

- News & Trends

- Exhibitions

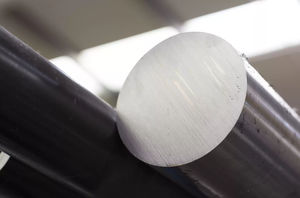

Tubular alloy steel Sanmac® 2205for the plastics industrycorrosion resistanthigh-strength

Add to favorites

Compare this product

Characteristics

- Shape

- tubular

- Applications

- for the plastics industry

- Other characteristics

- corrosion resistant, high-strength, annealed, stainless steel

Description

Sanmac® 2205 is a 22% Cr duplex stainless steel, supplied in the solution annealed condition, with improved machinability as standard. As a duplex stainless steel, it combines the desirable aspect of properties of both austenitic and ferritic grades. The high chromium, molybdenum and nitrogen contents results in a Pitting Resistance Equivalent number (PREN) of 33-34, providing pitting and crevice corrosion resistance superior to Alloy 316L or Alloy 317L austenitic stainless steels in almost all corrosive media. Due to its excellent corrosion properties, it is well-suited to environments containing chlorides and hydrogen sulphide, for use in oil & gas extraction from sour wells, in refineries and in process solutions contaminated with chlorides.

It also has good erosion fatigue properties as well as lower thermal expansion and higher thermal conductivity than austenitic steels. The yield strength is about twice that of austenitic stainless steels, allowing a designer to save weight and make the alloy more cost competitive when compared to Alloy 316L or Alloy 317L.

Sanmac® 2205 has been developed to provide superior machinability as standard. Control of composition and inclusion type results in improved chip formation and reduced tool wear, providing great machining productivity and lower tool costs.

Key Features:

Lower thermal expansion than austenitic stainless steels

Higher thermal conductivity than austenitic stainless steels

Applications:

Process industry components in sulphuric acid, nitric acid, phosphoric acid, ethylene oxide, polypropylene & PVC production

Equipment handling organic & fatty acids, chemical storage, tankers, heat exchangers

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.