- Hydraulics - Pneumatics

- Pipe, Tube and Fitting

- Socket fitting

- Langley Alloys Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

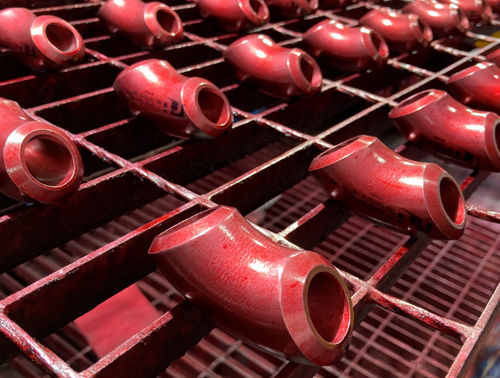

Socket fitting elbowISOPVC

Add to favorites

Compare this product

Characteristics

- Attachment

- socket

- Configuration

- elbow

- Norms

- ISO

- Material

- PVC, steel alloy

- Other characteristics

- forged

- Diameter

Min.: 0.25 in

Max.: 4 in

Description

The sourcing of fittings can be a challenging and time-consuming process given the immense number of different configurations. Fortunately, Langley Alloys is well-placed to source and manufacture fittings for your project, using our extensive supplier relationships and in-house capabilities.

There are a great variety of forged fittings that can be utilised to complete a pipeline system, such as Elbows, Tees, Reductions, Caps, Stub Ends, Couplings, Nipples and Olets. The number of possible combinations is immense, to accommodate both metric and Imperial pipe sizes, alloy type and piping configuration. For instance, Elbows can be offered with either a long or short radius, whilst Tees can be concentric or eccentric, adding to the number of product variations. The fittings can be joined to lengths of pipe via welding, either with a Socket Weld (SW) or Butt Weld (BW) finish or a Threaded (THRD) or Screwed (SCRD) connection. Each of these variables makes it less and less likely that a single manufacturer can provide the full range needed for a given project.

Langley Alloys can offer a complete package-building service to cover maintenance, repair and operation (MRO) requirements up to complete new-build projects. Forged fittings most typically cover specifications from ¼” to 4” NB (nominal bore), 3000-9000lbs ratings and supplied with alloys that meet the requirements of NACE MR 0175 / ISO 15156-3.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.