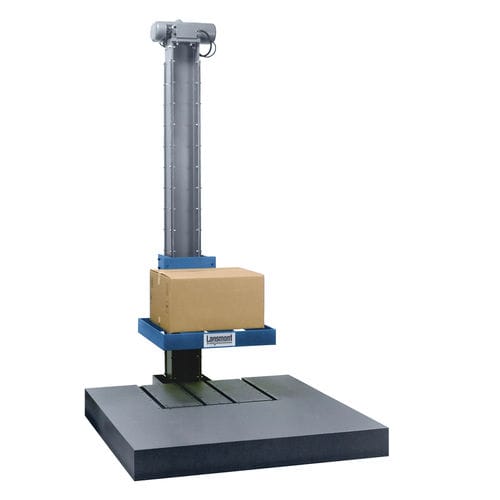

Large packaging drop tester PDT 300for heavy packaging

Add to favorites

Compare this product

Characteristics

- Applications

- for large packaging, for heavy packaging

Description

The PDT 300 accommodates drop testing applications for large products and packages such as returnable bulk containers, crated products, or palletized products weighing up to 661 lbs. (300 kg).

The PDT 300 utilizes a welded steel drop carriage, guided by precision bearing assemblies on a structural steel guide beam. The drop carriage is raised and lowered by an electric hoist. During the drop test, the drop carriage is accelerated downward, allowing the test item to free fall.

The standard drop carriage will hold test items with a front-to-back dimension up to 41.5 in. (105 cm). Two longer drop carriages are available which increases the front-to-back depth to as much as 118 in. (300 cm). Foundation kits and steel baseplates are available for all three drop carriage sizes.

The PDT 300 handheld controller lets the user safely move the drop carriage up and down, set the drop height, and perform the drop test operation.

Features highlights

• Spring-loaded pulley design helps to accelerate carriage downward, away from test item during a drop sequence. The system is designed and factory-verified to perform extremely accurate, flat drop testing that exceeds industry standards, such as ASTM D5276.

• Handheld control, allowing for positioning of the drop assembly, triggering of the drop sequence, and resetting of the drop platen.

• Edge & corner fixture, allowing controlled drop orientations of DUT.

• Electric hoist, providing automatic positioning of drop assembly with DUT.

Specification highlights

Max Payload:

661 lbs. (300 kg) – Standard Platen

661 lbs. (300 kg) – XL Platen

500 lbs. (227 kg) – XXL Platen

VIDEO

Catalogs

Related Searches

- Test machine

- Material testing machine

- PC-controllable testing machine

- Vertical test machine

- Industrial test machine

- Laboratory test machine

- Industrial testing system

- Precision test machine

- Electromechanical test machine

- Hydraulic test machine

- Quality control test machine

- Digital test machine

- Mechanical test machine

- Packaging test machine

- Static testing machine

- Tester with LCD screen

- Benchtop testing system

- Compact testing system

- Horizontal test machine

- Tabletop testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.