Vibration testing machine 56000semi-automaticfor packagingservo-hydraulic

Add to favorites

Compare this product

Characteristics

- Test type

- vibration

- Operating mode

- semi-automatic

- Test material

- for packaging

- Technology

- servo-hydraulic, closed-loop

Description

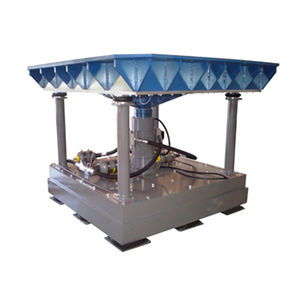

The Lansmont Model 56000 vibration test system utilizes dual 28000 vibration test systems working together in tandom to create large scale high performance.

Lansmont’s TouchTest Vibration Controls completely integrate all of the test hardware, operating controls, data analysis and reporting functions.

The system can perform random vibration, Field-to-Lab® simulations and direct downloads from Lansmont’s SAVER field data recorder, resonance search and dwell, sine sweep and repetitive bounce, all under closed-loop computer control.

All of Lansmont’s standard servo-hydraulic vibration test systems include the following:

• Single control system for all operational and safety functions

• Reliable, self-contained hydraulic power supply

• Lansmont initiation and system level training

• Full range of applications training programs available

• Comprehensive one-year warranty on all components

Features highlights

• Full Waveform Recorder

• User-Programmable Trigger Threshold

• Pre-Trigger Recording (so you know what happened before the event took place)

• 30-Day Continuous Event Recorder

• Shock LED Indicator

• Push button, delayed start or instantaneous activation

• USB connectivity for communication and instrument power for continuous, non-interrupted operations

• Rechargeable Batteries

• Utilizes SaverXware Software for Setup, Communication and Data Analysis

• Small footprint and form-factor allows embedding within the product and/or package system

Specification highlights

Piston Stroke: 2.5″ (6.4cm)

Options highlights

• External Power for Extended Run-Time

• Mounting Kits Including Magnets and other Attachment Hardware

• Data Analysis Services

Catalogs

No catalogs are available for this product.

See all of Lansmont‘s catalogsRelated Searches

- Test machine

- Material testing machine

- PC-controllable testing machine

- Vertical test machine

- Industrial test machine

- Laboratory test machine

- Industrial testing system

- Precision test machine

- Electromechanical test machine

- Hydraulic test machine

- Quality control test machine

- Digital test machine

- Mechanical test machine

- Packaging test machine

- Static testing machine

- Tester with LCD screen

- Benchtop testing system

- Compact testing system

- Horizontal test machine

- Tabletop testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.