- Production Machines

- Other Manufacturing Equipment

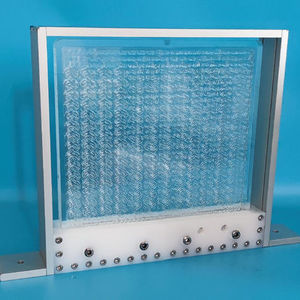

- Fluidized bed reactor

- Laryee technology co.,ltd

Photochemical processes reactor CM-DG&PG continuousfluidized bedlaboratory

Add to favorites

Compare this product

Characteristics

- Type

- continuous, fluidized bed

- Applications

- laboratory, photochemical processes, for the pharmaceutical industry

- Operation

- semi-automated

- Function

- synthesis, for catalyst screening

- Configuration

- modular

- Temperature

- cooling, with accurate temperature control

- Treatment method

- chemical

- Number of reactions

- multiple

- Material

- glass

- Other characteristics

- micro, safe

Description

A Photochemical reactor is a device that uses light (Photon) to perform a chemical reaction. Typically, the chemical reactions need a high temperature (about 100 to 250 degrees Celsius) for a large production scale. However, this process also gives useless byproducts and losses. With the help of a photoreactor, the process of material synthesis becomes easy. It is efficient and does not produce unwanted byproducts. Mainly this reaction carries out in the presence of photon and catalyst; hence it is called a Photocatalytic reactor. The process of photochlorination, water splitting, aflatoxin production, sulfonation, sulfoxidation, and nitrosylation can be performed successfully using this reactor setup. The reactor is also known as a UV reactor because the “light” we talk about here is commonly ultraviolet light. Comparing it to the traditional methods is much more reliable, consistent, and precise and gives opportunities to explore photochemistry.

Catalogs

No catalogs are available for this product.

See all of Laryee technology co.,ltd‘s catalogsOther Laryee technology co.,ltd products

Continuous Flow Reactor/ Glass flow reactor/Microfluidics/Modular reactor/Kilo-scale microreactor

Related Searches

- Laboratory-scale reactor

- Process reactor

- Pressure reactor

- Steel reactor

- Chemical reactor

- Reactor for the pharmaceutical industry

- High-temperature reactor

- Continuous-flow reactor

- Multiple reactor

- High-pressure reactor

- Glass reactor

- Synthesis reactor

- Low-temperature reactor

- Modular reactor

- Pilot reactor

- Catalytic reactor

- Large reactor

- Reactor with thermostat

- Safe reactor

- Micro reactor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.