Optical imaging system LDDinspection

Add to favorites

Compare this product

Characteristics

- Options

- optical

- Applications

- inspection

Description

Laser Depth Dynamics’ (LDD) patented imaging technique is the only technology that delivers direct, geometric measurements of laser weld penetration – during the weld. Inline Coherent Imaging, or ICI, uses a low-power IR laser beam to gauge distances and the extra distance from the material surface to the bottom of the keyhole is the weld penetration. This measurement beam is directed through the same optics as the welding beam, getting focused right to the bottom of the keyhole’s vapor channel and returning the actual penetration in real time. The resulting data is equivalent to a lengthwise section of the weld, delivered instantly, with no additional labor and without destroying the part. No more destructive testing and weld quality data saved for each weld produced.

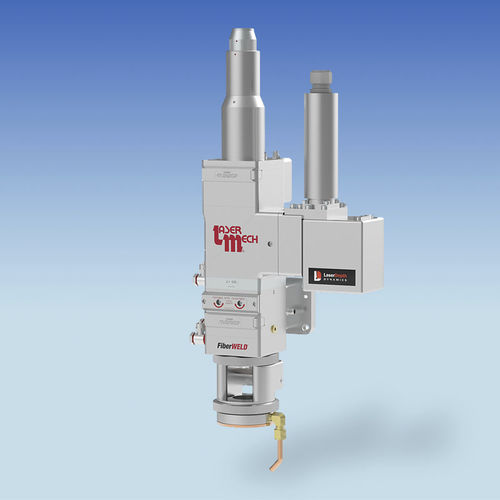

Laser Mechanisms has designed the LDD system seamlessly into all of its FiberWELD® heads and it can also be integrated into Laser Mech® CO2 beam delivery systems

Inline Coherent Imaging (ICI) is flexible, with applications in a range of laser processes beyond welding, and the ability to measure a growing number of process-specific metrics. ICI-based seam tracking, height following, spot weld penetration and solidified surface inspection are just a few examples for welding applications. It can measure the surface features and depth of an ablation laser, as well as serve as a pierce through detector in aerospace drilling. For additive processes, such as laser cladding and laser additive manufacturing, the ICI system can measure surface heights before and after another layer is added.

The LD-600 is LDD’s flagship inline coherent imaging system.

Catalogs

No catalogs are available for this product.

See all of Laser Mechanisms‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.