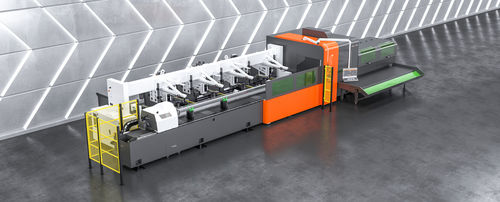

• Pipe and Profile Fiber Laser system is used to process pipes or profiles produced in different materials and shapes in many sectors such as agricultural machinery, machine tools, defense industry, Automotive sector and industrial shelf sector.

• The machine is suitable for pipe, square profile, rectangular profile cutting.

• The machine can be produced with 2kW, 3kW and 4kW power options

• Profiles or pipes in bales are loaded into the machine by an automatic loading system.

• The maximum cross-section that can be cut in the machines is 200mm X 100mm for profiles, Ø226mm for pipes.

• The machine can work for profiles or pipes up to 6500mm in length.

AUTOMATIC CENTERING

The automatic centering system determines the misalignment by checking in real-time whether the material fed to the machine and ready for cutting is in the center of the chuck. In addition, this option measures the outer dimensions ofthe material and the corner radius and checks the accuracyof the information entered into the system, ensures the continuity of the cut.

WELD SEAM DETECTION

Detection of weld seams in pipes and tubesprior to laser cutting is gaining importance due tothe ever-increasing use of welded pipes and tubes.In the industry more and more structural andsafety related components are made of welded tubes.The repeatability and efficiency required for theseoperations can only be achieved by preciselypositioning the weld seam before laser cutting.