- Hydraulics - Pneumatics

- Filter and Separator

- Chemical product filter cartridge

- LATTY INTERNATIONAL

Chemical product filter cartridge finemetalfor general purposes

Add to favorites

Compare this product

Characteristics

- Media

- for chemical products

- Type of filtration

- fine

- Material

- metal

- Applications

- for general purposes, for filters, for pharmaceutical applications

- Domain

- industrial, for the pharmaceutical industry, for the food industry, chemistry

Description

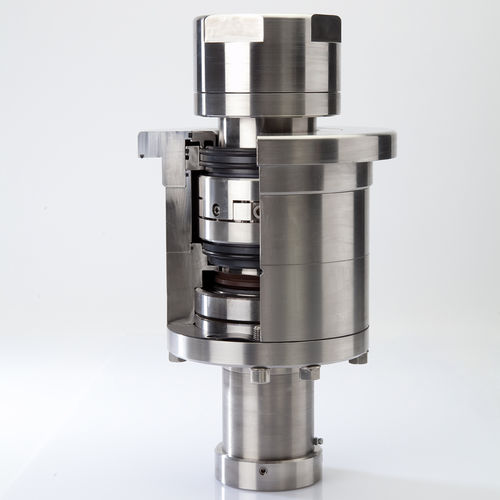

SEALING SOLUTION FOR CARTRIDGE MIXER SEAL

Agitation reduces the time for the heat transfer to products, contributes to the reduction of process times, speeds up reactions, promotes product homogenisation, filtration, smoothing and drying.

Dimensional characteristics, motor power, pressure ranges and temperatures vary from process to process.

All the criteria and parameters mentioned above are necessary to determine the solution and position of the seal. Our experience in the solutions proposed guarantee the durability of your installations and optimisation of maintenance operations.

Industries and equipment

Agitation is a major operation in many areas such as pharmaceuticals, chemicals, food processing, petrochemicals, etc.

Agitation equipment may be based on different designs (filters, dryers, reactors, etc.) depending on the industries, products and specifications. The equipment is made up of a drive, a bearing, one or several seals, a shaft associated to one or several propellers and a vessel.

• Industries : Pharmaceuticals, chemicals, food processing, cosmetics

• Equipment: agitator, reactor, filter-drier, polymeriser, mixer, crusher

• Medium: powder, gas, steam, toxic fluid, non-toxic fluid

Position of the sealing system depending on the agitation

In order to best determine the most appropriate seal, the positioning of the seal in the vessel will precisely help define the best-adapted seal type and technology for optimum performance. The service and environmental parameters are also accounted for in the specification

Catalogs

No catalogs are available for this product.

See all of LATTY INTERNATIONAL‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Hyvolution 2025

28-30 Jan 2025 paris (France) Stand 6F58

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.