- Food industry

- Dairy processing

- Cheese food mold

- Laude – A Tetra Pak company

- Products

- Catalogs

- News & Trends

- Exhibitions

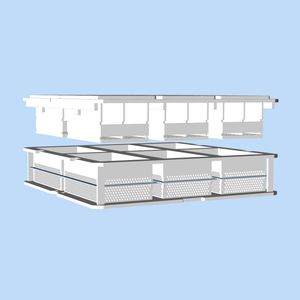

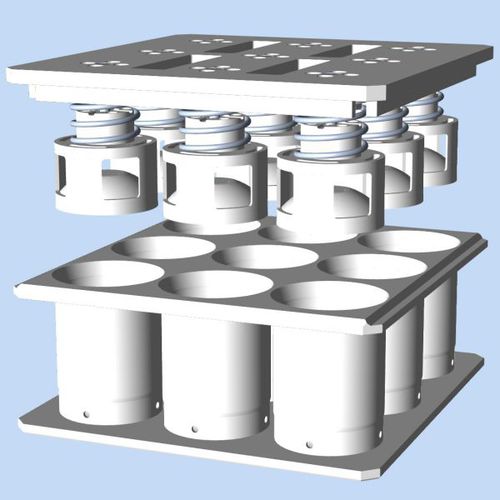

Cheese food mold roundverticalmulti-cavity

Add to favorites

Compare this product

Characteristics

- Food product

- for cheese

- Type

- round, vertical

- Other characteristics

- multi-cavity

Description

Instead of making single Edam ball cheeses, this multi-mould can produce 9 pieces in one time. The mould is specially designed for usage in a fully automated production line. It is a combination of polyethylene (top- and bottom plate) and polypropylene (shaft of the mould and lidcups) and stainless steel springs.

The advantage of springs is that they evenly distribute the pressure to the curd blocks/cheeses to make sure every cheese gets the same pressure.

All the dimensions of this mould can be adjusted based on your demand. Please contact one of our sales representatives to discuss the possibilities.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.