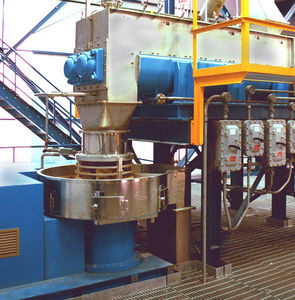

Wet granulator TDG-80Gfor pharmaceutical applicationsfor the food industryfor the chemical industry

Add to favorites

Compare this product

Characteristics

- Type

- wet

- Sector

- for pharmaceutical applications, for the food industry, for the chemical industry

- Other characteristics

- high-shear

Description

The wet mix, which is typically prepared in a kneader, pug mixer or high shear granulator (pharma), is metered into the feed hopper by a feeder or hand fed. Twin screws transport the wet mix to the extrusion zone where it is then wiped through a dome die (screen) to produce well formed, cylindrical extrudates of a controlled diameter. The extrudates break off by their own weight and are collected for the next processing step.

Low pressure extrusion with negligible heat generation

Screw transport ensures plug flow, first in first out

Easy-to-clean clamshell design extrusion chamber for easy access to process parts

Hydraulic clamping system for ease of disassembly

Minimal holdup volume

Easy scale-up

High yield

Better particle size distribution

Improved flowability

Excellent process repeatability

VIDEO

Catalogs

No catalogs are available for this product.

See all of LCI‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.