- Metrology - Laboratory

- Metrology and Test Equipment

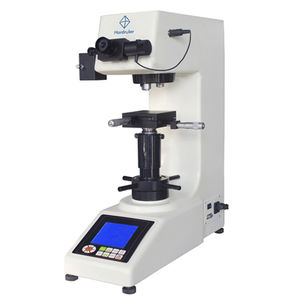

- Micro Vickers hardness tester

- Leader Precision Instrument Co. Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Micro Vickers hardness tester HV-1000benchtopfor non-ferrous metalsfor steel

Add to favorites

Compare this product

Characteristics

- Type

- micro Vickers

- Mounting

- benchtop

- Product applications

- for non-ferrous metals, for steel, for coatings, for plastics, for ceramics, for glass, for thin workpieces, for wafers

- Other characteristics

- LCD digital display

Description

The HV-1000 range of hardness testers makes use of the Micro-Vickers Hardness test to quantify the hardness of various metals and non-metals. It is particularly useful to test the Vickers hardness of non-iron metals, steel, specially-treated metallic layers and ceramics. It is used to evaluate the hardness grades of nitrided, carburized and hardened metallic layers.

Since the hardness tester uses micro-indentation, it is especially suited to test the Vickers hardness of ultra-thin components. The load, dwell and unloading functions are completely automatic. It can handle testing loads of 10, 25, 50, 100, 200, 300, 500 and 1000 gf and optionally 2000gf, i.e 2kg weight optionally. It is equipped with a wide range of testing forces of 0.098, 0.245, 0.49, 0.98, 1.96, 2.94, 4.9 and 9.8 N, for the efficient testing of an array of materials.

The tester can test hardness in a range of 8HV to 2900HV. The load dwelling time is typically 0-60s and can be adjusted as desired. The microscope produces magnified images to the tune of 10x for observing and 40x for measuring the indentation. It is equipped with an integrated thermal printer. The hardness tester is provided with an optional CCD imaging unit to facilitate video measurements.

The HV-1000 is perfectly suitable for determining the Vickers hardness of materials like IC wafers, metal foils, thin plastic, coatings, platings and surface layers, laminated metals, gems, agate, glass, ceramics, gradient of carburized and flame-hardened metallic layers.

Catalogs

Other Leader Precision Instrument Co. Ltd products

Hardness Tester

Related Searches

- Measuring device

- Measuring machine

- Indentation hardness tester

- Benchtop indentation hardness tester

- Digital hardness tester

- Digital measuring device

- Thickness measuring machine

- Portable measuring device

- Automatic test equipment

- Rockwell indentation hardness tester

- Brinell indentation hardness tester

- Vickers indentation hardness tester

- Optical measuring machine

- Automatic measuring machine

- Industrial gauge

- Automatic indentation hardness tester

- Moisture meter

- Metal indentation hardness tester

- High-precision measuring machine

- Measuring system for industrial applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.