- Robotics - Automation - Industrial IT

- Industrial Software

- Analysis software

- Leica Microsystems GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Analysis software LAS X Cleanliness Expertindustrialfor microscopesWindows

Add to favorites

Compare this product

Characteristics

- Function

- analysis

- Applications

- industrial, for microscopes

- Operating system

- Windows

Description

Your success depends on delivering customer satisfaction through high quality products. Cleanliness of parts and components determines performance, lifetime, and overall product quality.

As international and regional standards such as ISO, VDA and SAE become more strict in automotive and other industries, rigorous cleanliness analysis is necessary to ensure compliance.

Cleanliness Expert software is an easy-to-use, optimal solution to provide you with reliable, repeatable analysis results specific to your application needs.

Because cleanliness counts

• - Improve your workflow with multi-sample measurements

• - Meet international and national standards as well as individual requirements

• - Gain more information with laser spectroscopy to identify the source of contamination

Manage more than one sample

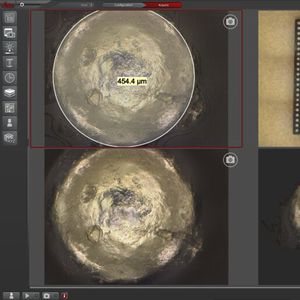

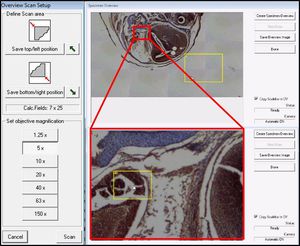

Analyze more than one sample at the same time, improve your workflow efficiency and simplify your process with automated particle analysis. Combine for example multiple filter samples from one filtration process into a single batch for analysis and assign different settings for particle classification for each filter. Generate reports easily to share your results.

Now you can

• - Save time by analyzing more than one filter at a time per batch

• - Set different parameters for particle classification, such as length and width limits for each filter

• - Measure with round or rectangular scanning patterns

• - Use the microscope for other tasks besides technical cleanliness analysis

Meet or exceed standards

Inspection is an important step in product safety, and is key for reliability and conformity to standards.

VIDEO

Catalogs

Leica Cleanliness Expert

4 Pages

Other Leica Microsystems GmbH products

Microscope Imaging Software

Related Searches

- Analysis software solution

- Leica Windows software

- 3D software solution

- Industrial software solution

- Quality software

- Inspection software

- Laboratory software

- Production software solution

- Imaging software

- Quality control software solution

- Metrology software

- Leica microscope software

- Steel construction software

- Steel construction software

- Microscopy software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.