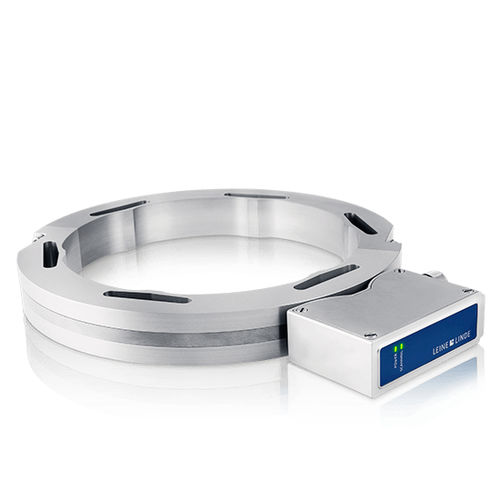

magnetic ring encoders for large shafts

Without ball bearings or other contact surface, Leine Linde’s magnetic ring encoders are practically immune to mechanical wear. The encoders are made in light-weight aluminium with an anodized surface for problem-free use in salt water environments. The sensor heads use several market standard interfaces for incremental signals. The interface High-Current HTL has been specially designed for long distance transmission.

Flange-mounted bearingless ring encoders

The MRI 2200 encoders are made with a flange-mount design, where axial screw holes in the ring enable fixing to a flange expansion on the application’s mating shaft. The ring is segmented into pieces and can be mounted from two sides of the shaft, thereby making commissioning easy. Between the ring and its sensor heads a gap is allowed in order to permit thermal expansion or runout of the application’s mating shaft. Radial tolerance is 0.1-3 mm and axially a ±4 mm offset is allowed for model 2202. For model 2206 an even wider extended scanning gap is permitted.

ClampFit-mounted bearingless ring encoders

The MRI 2300 encoders have a ClampFit mounting solution. This simplifies the manner of fixing the ring to any standard cylindrical shaft. When the ring segments are screwed together, the tethers will automatically tighten the ring to the mating shaft with radial force. This enables fixing to a standard cylindrical shaft without flange expansions having to be prepared. Mounting and retrofitting with this encoder becomes very easy.