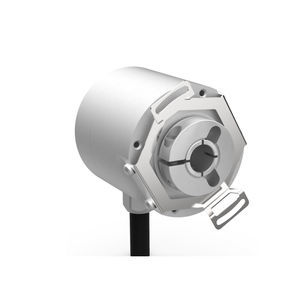

Incremental rotary encoder MZI 594magneticinductive24 Vdc

Add to favorites

Compare this product

Characteristics

- Type

- incremental

- Technology

- magnetic, inductive

- Supply voltage

- 24 Vdc, 15VDC, 12 Vdc, 9VDC

- Material

- aluminum, stainless steel

- Protection level

- robust, IP69K, IP69

- Other characteristics

- compact, bearingless

- Incremental encoder résolution (pulses per revolution

2,048 unit

- Housing diameter

74 mm

(2.91 in)- Shaft diameter

59 mm

(2.32 in)- Length

1.5 m

(4'11" )- Rotational speed

6,000 rpm

(37,699 rad.min-1)- Output frequency

Max.: 2,000 Hz

Min.: 10 Hz

- Process temperature

Max.: 100 °C

(212 °F)Min.: -40 °C

(-40 °F)

Description

Developed in collaboration with wind turbine manufacturers

Wind turbines, with encoder applications such as generator speed feedback, often comes with specific challenges. The turbines are often installed in hard-to-access locations, where encoders must endure really rough conditions.

This type of inductive incremental encoder was developed based on what wind turbine producers have kept on asking for: long lifetime, minimized impact on performance due to environmental conditions and ease of installation and commissioning.

The result is an inductive 58 mm incremental encoder in a bearingless design.

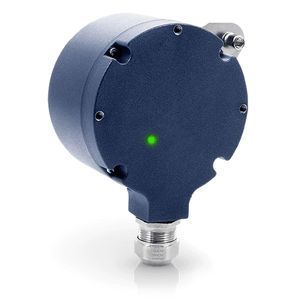

Superior lifetime due to bearingless design

Sliding shaft arrangement to compensate for thermal impact

Scanning quality is unaffected by humidity, dust and other contamination

Immune to electrical or magnetic fields due to the inductive scanning technology

Compact (ø58 mm x 45 mm) and very easy to install correctly

With the use of inductive scanning, the encoder can deliver high resolution - up to 8192 pulses per revolution - with high accuracy and unaffected by humidity or contamination. Its lifetime is not restricted by wear on the bearings. The bearingless design also make for a very compact solution. The unique sliding shaft design automatically compensates for movements of the generator or motor rotor shaft caused by thermal expansion.

All in all, this encoders is a very robust 58 mm encoder that will keep on doing its job year after year, with or without your attention. It is one of our future “silent” heroes.

Catalogs

No catalogs are available for this product.

See all of Leine & Linde‘s catalogsRelated Searches

- Angular encoder

- Incremental encoder

- Incremental rotary encoder

- Absolute rotary encoder

- Solid-shaft rotary encoder

- Hollow-shaft rotary encoder

- Optical rotary encoder

- Industrial rotary encoder

- Magnetic rotary encoder

- Limit switch

- IP67 rotary encoder

- Aluminum rotary encoder

- DC rotary encoder

- Compact rotary encoder

- Stainless steel rotary encoder

- Flange rotary encoder

- Linear encoder

- Robust rotary encoder

- Rotary encoder with SSI interface

- 5 VDC rotary encoder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.