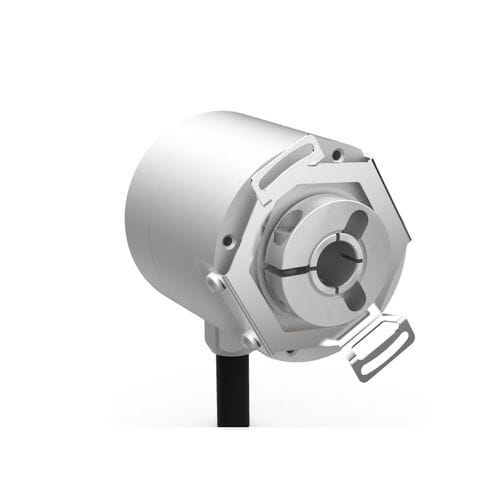

Incremental rotary encoder MHI 594 12thsmagneticinductivehollow-shaft

Add to favorites

Compare this product

Characteristics

- Type

- incremental

- Technology

- magnetic, inductive

- Construction

- hollow-shaft

- Supply voltage

- 24 Vdc, 15VDC, 12 Vdc, 9VDC

- Material

- aluminum, stainless steel

- Protection level

- standard, robust, IP67, IP66

- Shaft diameter

59 mm

(2.32 in)- Length

1,500 mm

(59.055 in)- Rotational speed

6,000 rpm

(37,699 rad.min-1)- Output frequency

100 kHz

- Process temperature

Min.: -20 °C

(-4 °F)Max.: 100 °C

(212 °F)

Description

Developed in partnership with crane manufacturers

Our crane customers have used our encoders on hoist motors with good results for several decades. Of course, there have been lots of development, adaptions and improvements made to the products over the years, to tailor them for the industry. With this new inductive encoder we are taking a bigger leap – this is our most robust ø58 mm encoder ever.

The inductive scanning used on these incremental encoders is unaffected by magnetic fields which sometimes are imposed by break systems mounted on the motors. The encoder’s large bearing dimension together with its hollow-shaft design make for an increased operational lifetime and a unit that is easier to install compared with its predecessors. We removed small screws and washers, and adjusted the dimensions for easier installation by “big hands” working in cold climates.

Improved lifetime due to larger bearings

Self-contained bearing-based system mounting, compatible to industry standard interfaces

Scanning unaffected by magnetic influence imposed by electric motors and break systems

Insensitive to contamination, salt water and break dust

Only 1 tool required for installation

Catalogs

No catalogs are available for this product.

See all of Leine & Linde‘s catalogsRelated Searches

- Angular encoder

- Incremental encoder

- Incremental rotary encoder

- Absolute rotary encoder

- Solid-shaft rotary encoder

- Hollow-shaft rotary encoder

- Optical rotary encoder

- Industrial rotary encoder

- Magnetic rotary encoder

- Limit switch

- IP67 rotary encoder

- DC rotary encoder

- Aluminum rotary encoder

- Compact rotary encoder

- Stainless steel rotary encoder

- Flange rotary encoder

- Linear encoder

- Robust rotary encoder

- Rotary encoder with SSI interface

- 5 VDC rotary encoder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.