- Industrial machines and equipment

- Surface Treatment

- Hot dip galvanizing

- Leist Oberflächentechnik GmbH & Co. KG

- Products

- Catalogs

- News & Trends

- Exhibitions

Hot dip galvanizing steelindustrialmedium series

Add to favorites

Compare this product

Characteristics

- Process

- hot dip

- Type of substrate

- steel

- Applications

- industrial

- Production method

- medium series, large series, small series

- Certifications

- ISO 14001

Description

With hot-dip galvanizing, the material to be galvanized is immersed in molten zinc. As a consequence of the mutual diffusion, a layer of differently composed zinc-iron alloy layers forms between the zinc and the steel surface, whereby a coating of pure zinc usually remains on the outermost layer.

Hot-dip-galvanized parts are especially resistant against atmospheric, chemical, thermal and mechanical loads. Through the immersion in the liquid melt, cavities can also be reliably protected.

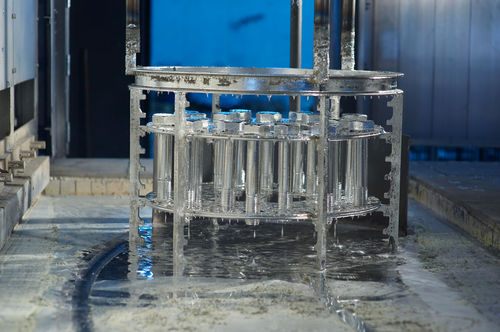

In the area of hot-dip galvanizing, we offer a unique, self-developed coating process using the rack process. The parts – such as screws for the wind power industry – that leave our system are “ready-to-build.” They can be installed directly with no thread rolling – which can damage the coating.

Other Leist Oberflächentechnik GmbH & Co. KG products

Services & Methods

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.