- Hydraulics - Pneumatics

- Pump

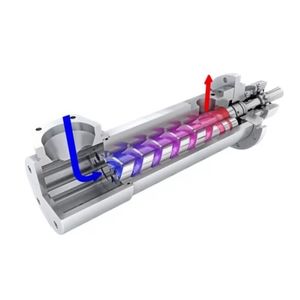

- 2 screws pump

- Leistritz Pumpen GmbH

2 screws pump L2Nfor coolantfor crude oiloil

Add to favorites

Compare this product

Characteristics

- Technology

- 2 screws

- Fluid

- for coolant, for crude oil, oil, fuel oil, diesel fuel, for bitumen and asphalt, for gas

- Operation

- with electric motor

- Priming

- self-priming

- Mobility

- stationary

- Domain

- industrial, for the chemical industry, for oil industry applications, for marine applications, for renewable energy

- Applications

- transfer, discharge, cooling, circulation, chemical process, for industrial applications, control, unloading

- Fluid specification

- for aggressive media, for abrasive fluids, for low-viscosity fluids, for medium-viscosity products, for corrosive fluids, for high-viscosity fluids, for mineral oil

- Protection level

- chemical-resistant

- Other characteristics

- compact, high-efficiency, heavy-duty, high-performance, low-noise, high-flow, low-pressure, electronic

- Flow

Min.: 12 m³/h

(423.776 ft³/h)Max.: 900 m³/h

(31,783.20005 ft³/h)- Pressure

Min.: 4 bar

(58.015 psi)Max.: 16 bar

(232.06 psi)- Fluid temperature

280 °C

(536 °F)

Description

Leistritz screw pumps in the L2 range are twin-screw, single-volute, self-priming positive displacement pumps for the low-pressure range. They are used to pump slightly aggressive, slightly abrasive, low to high-viscosity fluids with good to poor lubrication properties.

Leistritz screw pumps of the L2NG series, are self-priming positive displacement pumps for a pressure range up to 16 bar (232 psi), suitable for transport of light abrasive and corrosive, high or low viscous fluids with poor or good lubricity.

User benefits:

↗ High efficiency > Low operating costs

↗ Only one shaft seal > low-maintenance

↗ Suitable for short dry runs > Maximum process reliability

↗ Radial bearing brushes > Long service life

↗ Axially balanced rotors > no axial forces to bearings

↗ Low axial flow velocity > excellent priming

↗ Resistant against aeration > low noise, minimized vibration

↗ Availability of sealless design by magnetic drive

Catalogs

Leistritz product range

9 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.