- Hydraulics - Pneumatics

- Pump

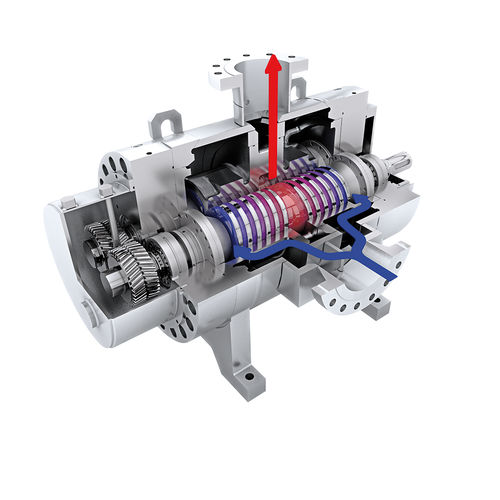

- Screw pump

- Leistritz Pumpen GmbH

Screw spindle pump L4 for crude oillubricating oilfuel oil

Add to favorites

Compare this product

Characteristics

- Technology

- screw spindle

- Fluid

- for crude oil, lubricating oil, fuel oil, for bitumen and asphalt

- Operation

- with electric motor

- Priming

- self-priming

- Mobility

- stationary

- Domain

- industrial, for oil industry applications

- Applications

- transport, unloading, loading

- Fluid specification

- for aggressive media, for abrasive fluids, for low-viscosity fluids, for high-viscosity products, for corrosive fluids, for fluids with lubricating properties

- Protection level

- chemical-resistant

- Flow

Max.: 5,000 m³/h

(176,573.33361 ft³/h)Min.: 2,000 m³/h

(70,629.33344 ft³/h)- Pressure

Max.: 150 bar

(2,175.566 psi)Min.: 16 bar

(232.06 psi)

Description

Leistritz screw pumps of series L4 are twin screw double volute, self-priming positive displacement pumps for low, medium and high pressure duty, suitable for transport of abrasive/non abrasive, corrosive/non corrosive, lubricating/non lubricating, high or low viscous fluids.In the oil & gas industry it is used as pipeline start-up, unloading, tank cleaning, stripping, transfer, booster, circulating, blending and export pump for all kinds of fluids, e.g. multiphase liquids, crude oils, produced water, crude oil/water emulsions, fuel oils, bitumen, tar, asphalt, grease, residues, paraffin, molten sulphur, kerosene, slops, drains and many more.

User advantages:

↗ Rotors (screws and shafts) made out of a single piece of bar stock

> Limited shaft deflection

> Low bearing loads

↗ Maximum allowable rotor deflection limited to 50% of radial clearance between rotor housing and rotor

> highest process safety

↗ Gear designs with helical gear teeth

> Reduced noise level

> Easy maintenance

↗ Interchangeable liner

> easy maintenance, low costs

↗ Special rotor design available

> Minimized pulsation

> Optimized NPSHr

↗ Low axial flow velocity

> excellent priming

↗ Axially balanced rotors

> no axial forces to bearings

↗ Suitable for dry running

> maximized process safety

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.