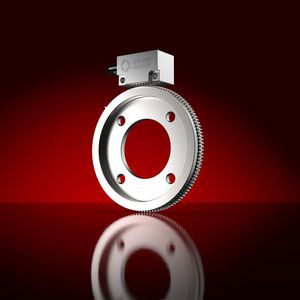

Incremental rotary encoder GEL 2444

Add to favorites

Compare this product

Characteristics

- Type

- incremental

Description

General

The measuring system comprises a MiniCODER and a

precision target wheel for attachment to shafts

The MiniCODER contactlessly scans the precision

target wheel using magnetoresistive sensors and

acquires the direction of rotation, rotational speed and

position

Features

Output signal level

1 Vpp Differential signal (sin/cos) or TTL / RS422

Analogue or digital reference pulse

Selection of interpolation factors to increase the number

of pulses per revolution possible

Recording of temperature and rotational speed

histogram and automatic calibration possible

Frequency range from 0 to 200 kHz (1)

Temperature range -40 °C to +120 °C

Protection class IP 68

Safety integrated certificate (signal pattern K)

Advantages

Maintenance and wear-free

Low temperature drift and high signal quality

Highest immunity to interference due to fully screened

metal housing

High design flexibility due to custom manufacture of

precision target wheels

Field of application

Machine tool engineering

- Position and rotational speed acquisition in HSC

spindles (High Speed Cutting)

- Electronic synchronisation of screw spindles in

vacuum pumps

- Position and rotational speed measurement in

lathes, grinding and milling machines

Rotational speed and position measurement in test

stands and motors (hybrid drives, torque motors)

Maintenance and wear-free

Low temperature drift and high signal quality

Highest immunity to interference due to fully screened metal housing

Records the minimum temperature, maximum temperature and rotational speed histogram

It can be calibrated automatically using the testing and programming unit

For target wheels with 10 mm and 12 mm thickness

Catalogs

Related Searches

- Angular encoder

- Incremental encoder

- Incremental rotary encoder

- Absolute rotary encoder

- Solid-shaft rotary encoder

- Hollow-shaft rotary encoder

- Industrial rotary encoder

- Magnetic rotary encoder

- IP65 rotary encoder

- IP67 rotary encoder

- Compact rotary encoder

- Stainless steel rotary encoder

- Flange rotary encoder

- Robust rotary encoder

- Rotary encoder with SSI interface

- High-resolution rotary encoder

- Mechanical rotary encoder

- Rotational speed sensor

- Magnetic speed sensor

- Miniature rotary encoder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.