- Hydraulics - Pneumatics

- Filter and Separator

- Polypropylene filter medium

- LENSER Filtration GmbH

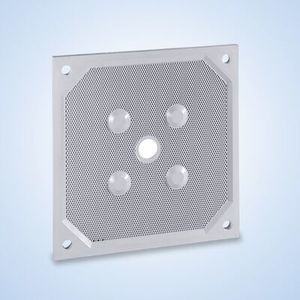

Polypropylene filter element KM bloc - Mairmembrane

Add to favorites

Compare this product

Characteristics

- Material

- polypropylene

- Applications

- air

- Other characteristics

- membrane

Description

As the inventor of the polypropylene filter element, membrane filter elements have been part of our core service from the very beginning. With LENSER membrane filter plates, you can significantly shorten your filtration process, increase the dry content of your cake and save enormous resources. This is made possible by mechanically squeezing the filter cake after the actual filtration process.

We develop and manufacture:

KM bloc - Membrane filter element, standard, welded

KM UM bloc - Membrane filter element, empty chamber, welded

KM UM HD bloc - High-pressure membrane filter element, empty chamber, welded

KM RUM - Membran filter element, exchangeable membrane half

KM RUD - Membran filter element, exchangeable membrane half

The recessed membrane allows a more uniform cake thickness and a very good washing result.

Advantages

Shorter filtration cycles

Shorter washing times

Higher dry solids content

Even cake thickness distribution across filtration area

Higher throughput rate

Reduced water consumption

Reduced air consumption during blow-drying

Superior cake washing/blowing results

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.