Low-voltage cable harness D-Sub

Add to favorites

Compare this product

Characteristics

- Cable type

- D-Sub, low-voltage

Description

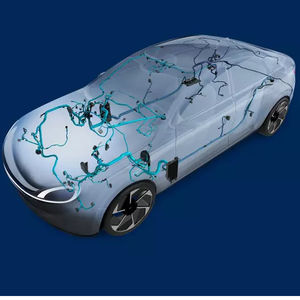

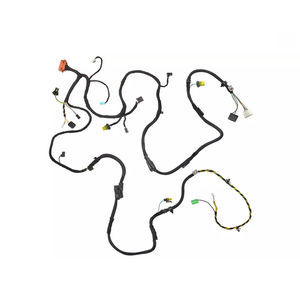

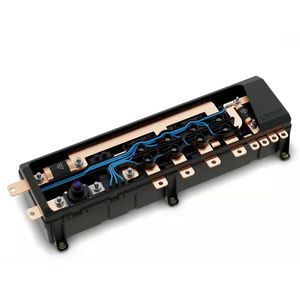

In addition to the minor or engine harness, special cable harnesses for certain applications are also necessary, as the requirements, such as temperature resistance combined with high vibration requirements and mechanical loads - stone chipping, for example - can vary greatly. So-called technical sub harnesses are used here. These are characterized by the use of special processes to meet customer requirements. These include overmolding, potting processes, foaming processes or surface preparation.

The fields of application for these processes include a wide range of products - from axle line sets to the AdBlue® Doser Harness, integrated sensor solutions or wiring harnesses in the transmission sector. Regardless of whether there are special requirements in terms of temperature and humidity, vibration, mechanical stress or chemical resistance: we reliably meet our customers' requirements with technical sub-harnesses.

• Technical sub-harnesses are cable harnesses for special applications that are developed using special processes to meet customer requirements

• These processes include, for example, overmolding, encapsulation, foaming processes, surface preparation and customized material selection

• As a result, requirements such as temperature and humidity, impermeability (IP class), vibration, mechanical stress (e.g. stone impact) and chemical resistance are met

Catalogs

No catalogs are available for this product.

See all of LEONI AG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.