Low-voltage cable harness antennafor automobiles

Add to favorites

Compare this product

Characteristics

- Cable type

- low-voltage, antenna

- Applications

- for automobiles

Description

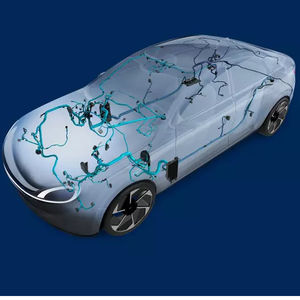

While most electrical systems in a motor vehicle are supplied by larger, more complex wiring harnesses - such as the body harness - there are cases where smaller, more discrete wiring solutions are required. Certain components of a vehicle are assembled outside the main assembly line at the OEM in separate areas. These include doors, seats, axles, bumpers and the dashboard. Therefore, specific wiring harnesses need to be connected to the main wiring harness after the final assembly of the vehicle. Therefore, these smaller harnesses offer OEMs the flexibility to manage their vehicle assembly while ensuring continuity of the electrical system in the final assembled vehicle. The possible technical designs range from a simple, unsealed single connection to a high-temperature multicore cable with overmolded connectors. The weight can be up to 3.5 kg for a dashboard with 200 cables and 50 connectors. Mostly copper cables are used, often antenna cables are also included. There is a wide range of technical specifications.

•Variant or customer-specific wiring harnesses

•A wide range of specifications can be covered

Catalogs

No catalogs are available for this product.

See all of LEONI AG‘s catalogsRelated Searches

- Electrical connector

- Electrical cable

- Data electrical connector

- Copper cable

- Electrical power supply connector

- Copper electrical cable

- Power cable

- Insulated cable

- Insulated electrical cable

- Terminal box

- Screw-in electrical connector

- Data electrical cable

- Metal box

- Flexible cable

- Wall-mounted terminal box

- Flexible electrical cable

- Cable connector

- IEC electrical cable

- Industrial cable

- Cable assembly

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.