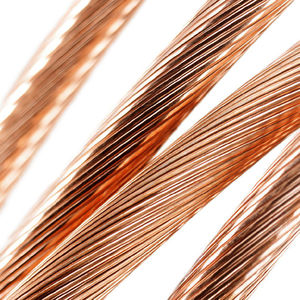

Copper electrical wire copper alloyflexibleround

Add to favorites

Compare this product

Characteristics

- Cable core material

- copper, copper alloy

- Structure

- flexible, round, multi-strand

- Applications

- for railway applications

Description

In semi-concentric strands, the individual wires are subject to an exact positioning, yet without an additional core wire, which ensures an all-out uniform structure.

Applications

• Extrusion: thin-gauge coating with high-grade isolation materials

Particular benefits for our customers

• Uniform elongation of single wires

• Low tolerances, even in single wires (even outperforming ASTM)

Manufacturing range

• Materials: Cu-ETP1 and Cu-OF1

• Bare, tin-plated, nickel-plated, silver-plated

• Left-hand lay or right-hand lay

• Variation: soft annealed

• Single-wire diameter: ranging from Ø 0.05 mm to Ø 0.51 mm

• Cross-section: ranging from 0.03 mm2 to 16 mm2

Construction

The following strand constructions are possible, which depend upon the number of core wires:

2 core wires:

2 + (2 + 6) = 10 ends

2 + (2 + 6) + (2 + 6 + 6) = 24 ends …

2 + ∑n (2 + n * 6)

3 core wires:

3 + (3 + 6) = 12 ends

3 + (3 + 6) + (3 + 6 + 6) = 27 ends …

3 + ∑n (3 + n * 6)

4 core wires:

4 + (4 + 6) = 14 ends

4 + (4 + 6) + (4 + 6 + 6) = 30 ends …

4 + ∑n (4 + n * 6)

5 core wires:

5 + (5 + 6) = 16 ends

5 + (5 + 6) + (5 + 6 + 6) = 33 ends …

5 + ∑n (5 + n * 6)

Packaging

Reel sizes from 80 mm (1 kg) to 630 mm (400 kg), subject to diameter

Related Searches

- Hook-up wire

- Copper hook-up wire

- Insulated hook-up wire

- Stranded electrical wire

- Flexible hook-up wire

- Round electrical wire

- Single-conductor electrical wire

- High-temperature hook-up wire

- High-voltage hook-up wire

- Hook-up wire for automotive applications

- Electric motor electrical wire

- Electrical wire for railway applications

- Silicone hook-up wire

- Mass braid

- Transformer electrical wire

- Telecommunication equipment electrical wire

- Aluminum electrical wire

- Electrical wire for medical applications

- Copper alloy electrical wire

- Electrical wire for marine applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.