- Industrial machines and equipment

- Mixing and Dosing

- Volumetric batch blender

- Lescuyer Villeneuve

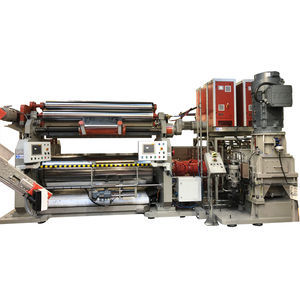

Twin-screw batch blender with belt feederautomatic

Add to favorites

Compare this product

Characteristics

- Type

- twin-screw

- Other characteristics

- automatic, with belt feeder

Description

Optimization and automation of rubber mixing lines

A mixing line must be designed according to the characteristics of the material and the product application. Our team is at your disposal to design or improve any mixing line thanks to a recognized expertise in the field of rubber transformation.

Our broad areas of expertise help us to disclose lines with internal mixers, several cylinder mixers, a Batch off type cooling system. This historical type of mixing lines is used in particular for materials with heat-sensitive additives.

Increasingly recognized as a viable solution, the use of a conical twin-screw mixer automates the downstream line. Indeed, this will create a buffer zone and can be fed directly by the internal mixer or by a mixing mill.

All our lines comply with industrial ergonomics and safety standards for each equipment: NF EN 12013, NF EN 1417.

CHARACTERISTICS

We also supply the additional line equipments as pulling units, dimensional control devices, feed belt, cutting machines and thermal systems.

Our teams therefore have full control of a mixing line to provide turnkey equipment with the delivery, installation and training of teams on site.

Vomery automatic mixing technology can be added to the mixnig mill to improve line repeatability while making the operator’s job easier.

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Solid blender

- Agitator for the chemical industry

- In-line mixer

- Mixer-dispenser

- Compact agitator

- Laboratory homogenizer

- Volumetric mixer-dispenser

- Rotor agitator

- Automatic mixing and metering unit

- Blending system

- Conical blender

- Modular agitator

- High-capacity blender

- Polymer agitator

- Automatic mixing system

- Mixer for the rubber industry

- Thermo-regulated mixer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.